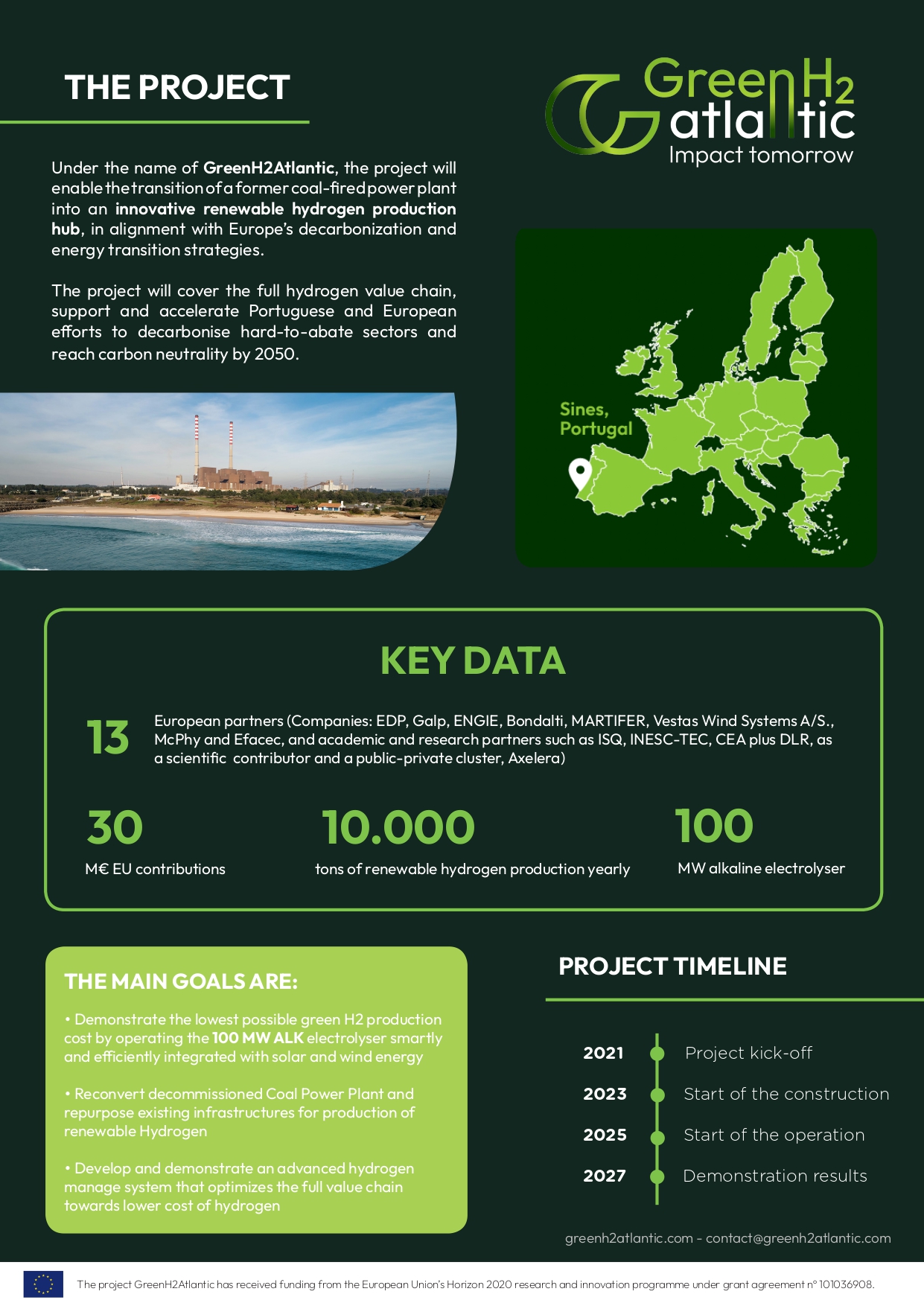

The GreenH2Atlantic project consists in a 100 MW flexible green hydrogen production to be installed in Sines, Portugal, to supply multiple end-uses. The consortium developing this project is composed of 13 European companies from the full value chain and of research partners, to which McPhy will bring the electrolysis technological brick.

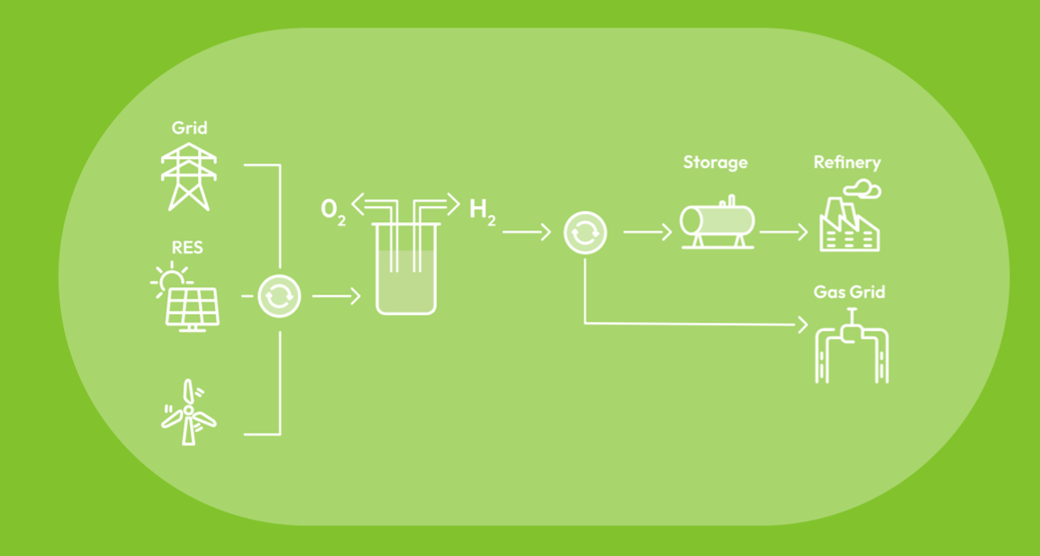

• Electrolysis: 100 MW electrolysis platform

• Innovative technology “Augmented McLyzer”: scalable and fast-cycling

• 41 tons of green hydrogen to be produced per day, 10 000 tons yearly and 80 kilotons of Co2 emissions avoided / year (equivalent of 18 700 passenger vehicles driven in one year)

• Industrial & energy uses: refinery and injection in the gas grid

• Construction expected start: 2024 | Operation expected start: by the end of 2026

With the creation of a ‘hydrogen valley’, GreenH2Atlantic will significantly contribute to the sustainability goals of the region and Portugal, providing an important contribution to the European energy roadmap.

Under the name GreenH2Atlantic, a consortium of 13 companies and research partners are selected by the European Commission as part of the Green Deal to develop a renewable hydrogen production hub at 100 MW scale in Sines, Portugal.

The consortium supporting this project includes McPhy and companies such as EDP, Galp, ENGIE, Bondalti, Martifer, Vestas Systems A/S and Efacec, and academic and research partners such as ISQ, INESC-TEC, DLR and CEA, in addition to a public-private cluster, Axelera.

GreenH2Atlantic was one of the three projects selected by the Horizon 2020 – Green Deal Call to demonstrate the viability of green hydrogen production on an unprecedented scale.

The 30 million euros grant will help to finance the construction of the hydrogen plant, located in the coal-fired power plant area in Sines. The construction should start in 2024 and operation is expected to begin in 2026, subject to securing the necessary authorizations by the authorities.

McPhy has been selected as preferred partner, with its innovative electrolysis technology “Augmented McLyzer” which will convert green electricity by electrolysis into more than 41 tons of clean hydrogen per day. This 100 MW electrolyzer will be composed of innovative, scalable and fast-cycling 16 MW modules designed, manufactured and integrated by McPhy. The electrolysis platform is to supply low-carbon hydrogen for industrial (refinery) and energy (injection in the gas grid) uses, upscaling the link between renewables and industry, mobility and energy applications.

Low-carbon hydrogen is expected to become one of the pillars of economic growth, for it is a decisive energy vector in the decarbonization process for the main sectors of the economy.

This project will enable the transition of a former coal-fired power plant into an innovative renewable hydrogen production hub and create a ‘hydrogen valley’ centered in Sines. GreenH2Atlantic will significantly contribute to the sustainability goals of the region and Portugal, providing an important contribution to Europe’s decarbonization and energy transition strategies.

Recently, in December 2022, The GreenH2Atlantic project, has been granted the PIN (Potential National Interest) status.

Funded by the European Union’s Horizon 2020 research and innovation program

The project GreenH2Atlantic has received funding from the European Union’s Horizon 2020 research and innovation program under grant agreement nº 101036908.

| Markets

- Industry

- Energy

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- “Augmented McLyzer” technology: 100 MW electrolysis platform

Learn more about the solutions in the section: “Equipment & Services”.

| Customer

- European Commission as part of the Green Deal

- Location: Sines, Portugal

- Construction expected start: 2024 | Operation expected start: end of 2026

- Project website : www.greenh2atlantic.com

- https://www.greenh2atlantic.com/partners/mcphy

Gallery

First Power-to-Gas project at a MW-scale in France

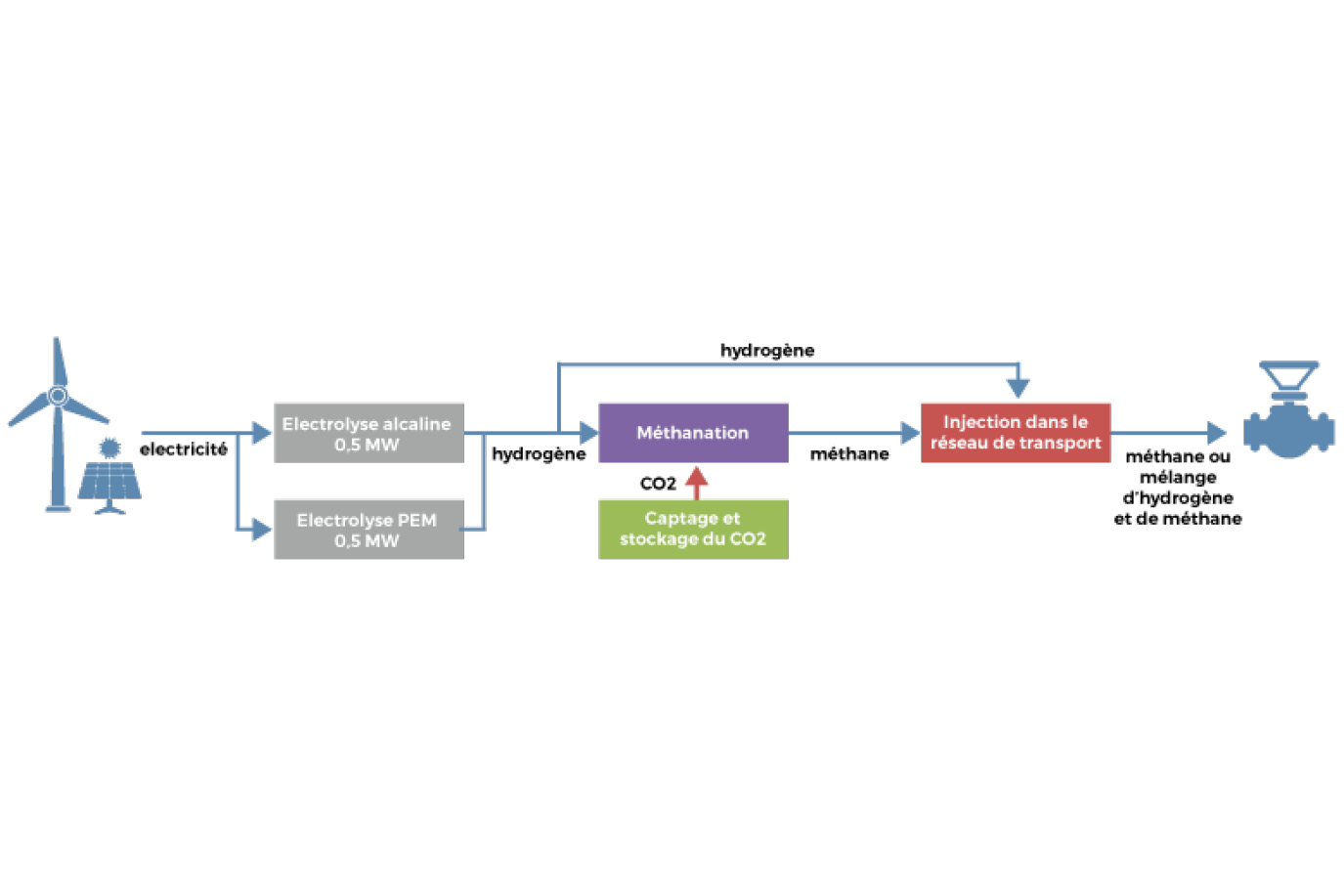

• GRTGaz has selected McPhy to equip the Jupiter 1000 project, which is preparing for the deployment of the Power to Gas network in France, with a 1 MW hydrogen production platform

• Testing the performance of two electrolysis technologies (alkaline & PEM) under real conditions and on a real scale

• Fos sur Mer, France | Commissioning: 2019

McPhy supplies a 1 MW hydrogen platform equipment made of a 0.5 MW alkaline electrolyzer and a 0.5 MW PEM electrolyzer, Jupiter 1000 is the only project that will make it possible, in the medium term, to test the performance of those 2 electrolysis technologies under real conditions and on a real scale.

Jupiter 1000 is the first Power to Gas project in France, aiming to store and valorize renewable electricity by injecting hydrogen and synthetic methane into the gas transmission network.

| Markets

- Power to Gas

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- Electrolyzers in 1 MW configuration (1 alkaline electrolyzer 0.5 MW & 1 PEM electrolyzer 0.5 MW)

Learn more about the solutions in the section: “Equipment & Services”.

| Customer

- GRTGaz

- Location: Fos sur Mer (France)

- Commissioning : 2018

Visit the Jupiter 1000 website

Read the press release

Gallery

By installing 4 MW of electrolysis capacity in China, McPhy demonstrates its expertise in managing international projects

• Zero-carbon hydrogen production platform (4 MW), from a wind farm

• Very fast dynamic response, adapted to renewable energy variations

• Strengthens McPhy’s positioning on international multi-MW projects

• Hebei Province, China | Delivery: 2017

McPhy offer tailor-made solutions to ensure a balance between energy supply and demand in the In the China Hebei province’ networks.

The solution delivered to Hebei Province is a compact 4 MW hydrogen generation equipment including two McLyzer 400-30 modules, transformers, power electronics, a purification and drying unit, as well as a solid-state storage module, initiating a complete chain of renewable electricity surplus valorization in the heart of China.

The McPhy system converts and stores renewable electricity surplus produced by a 200 MW wind farm into clean hydrogen. This project represents a major reference for McPhy, which confirms its ability to execute projects for the massive conversion of renewable energy into hydrogen for injection into the grid or as a raw material. As well as its ability to manage major international projects.

Perfectly adapted to the variability of renewable energies, McLyzer rapid response electrolyzers offer energy companies a relevant solution to ensure the stability of electricity networks.

| Markets

- Power to Gas

- Hydrogen territories

- Energy storage (solar park)

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- 2 McLyzer 400-30

Learn more about the solutions in the section: “Equipment & Services”.

| Client

- Jiantou Yanshan (Guyuan) Wind Energy

- Location: Hebei (China)

- Commissioning: 2017

Read the press release

Gallery

1 MW of electrolysis to support the valorization of the renewable energy surplus in Germany

• Contract with a leading energy company

• Very fast dynamic response, adapted to renewable energy variations

• Wyhlen, Germany | Commissioning: 2017

This project provides an efficient and competitive answer to the issues raised by renewable energies, which are intermittent in nature and need adapted storage and valorization solutions.

“This project will contribute to the development of renewable electricity sources in Germany, the world’s second largest renewable energy producer, by offering a competitive solution to valorize to production surplus”

McPhy has equipped in 2017 the site with a 1 MW zero-carbon hydrogen production plant and is supporting EnergieDienst in the valorization of this hydrogen in industry, zero-emission mobility or injection into gas networks.

| Markets

- Power to Gas

- Industrial hydrogen

- Energy storage (hydrolic power plant)

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- McLyzer 200-30

Learn more about the solutions in the section: “Equipment & Services”.

| Client

- EnergieDienst

- Location: Bade-Wurtemberg (Allemagne)

- Commissioning: end 2017

Read the press release

Since 2013, an industrial hydrogen production unit

• Precursor project of Power to Gas in Europe

• Electrolyzer plant and maintenance contract for the Audi’s e-gas plant

• Werlte, Germany | Commissioning: 2013

The 6 MW alkaline electrolyzer is a key component of e-gas power plant technology, making it possible to extract hydrogen from water using surplus electricity. Through its expertise, McPhy Energy’s subsidy in Wildau (Germany) has further optimized this technology ( today known as “Alcaline 2.0” electrolysis) and developed in-depth experience ensuring its integration into energy infrastructures such as electrical or natural gas networks.

The plant therefore uses surplus green electricity to produce hydrogen from water in three alkaline electrolyzers. The hydrogen is reacted with CO2 to produce synthetic methane, or Audi e-gas.

It is virtually identical to the fossil fuel and natural gas, and is distributed through an existing infrastructure, the German natural gas network, to CNG filling stations for Audi’s A3 g-tron series. Audi produces up to 1,000 metric tons of e-gas per year, chemically binding some 2,800 metric tons of CO2. This roughly corresponds to the amount that a forest of over 220,000 beech trees absorbs in one year. Water and oxygen are the only by-products.

| Markets

- Industrial hydrogen

- Power to Gas

- Hydrogen territories

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- 6 MW electrolysis solution

Learn more about the solutions in the section: “Equipment & Services”.

| Customer

- Audi

- Location: Werlte (Germany)

- Commissioning: 2013

Read the press release

Gallery

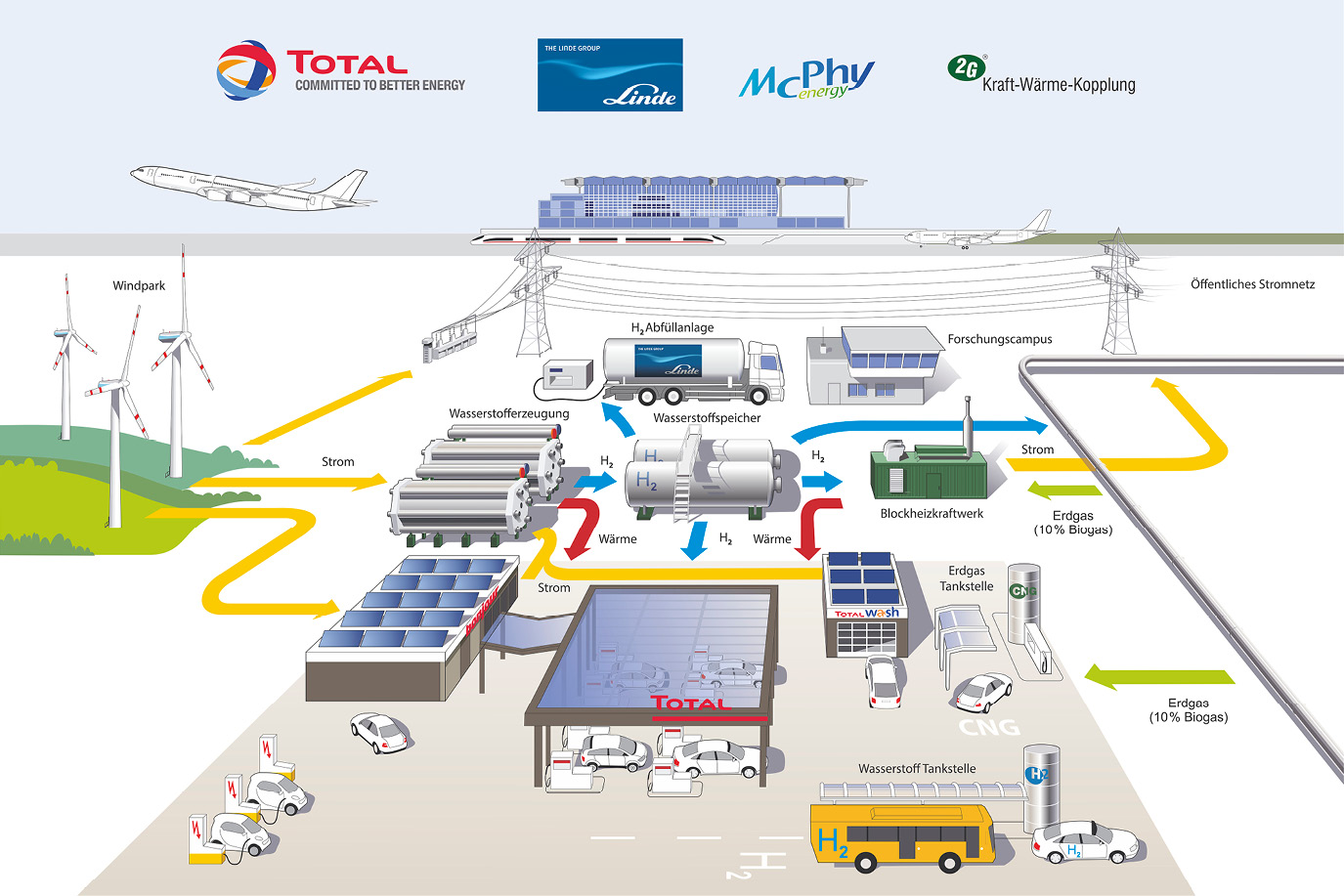

On-site hydrogen production for the first Total hydrogen station in Europe

• A full hydrogen system for mobility and network service

• First high-pressure alkaline electrolyzer on the market

• Connection to a wind farm and grids

• McLyzer performance data collection

• Berlin, Germany | Commissioning: 2014

Located at the Berlin Airport, this demonstration project is designed to produce “green” hydrogen from a surplus of wind power using an electrolyzer and using solid-state storage to create a hydrogen cogeneration plant and hydrogen filling-station infrastructure for buses and cars.

Renewable energy from the Enertrag wind farm near the new airport in Berlin will be converted into hydrogen by a McPhy electrolyzer, to smooth out energy fluctuations and store surplus wind energy.

Total and Linde will build the infrastructure necessary to distribute this fuel to buses and automobiles powered by fuel cells.

In addition, new-generation McPhy solid-state hydrogen-storage will allow the 2G power station to provide electricity or heat from stored hydrogen, flexibly and on demand.

The interests of this project are multiple:

- To produce zero-emission fuel for cars or buses running on hydrogen and/or supply other hydrogen filling stations.

- To re-inject surplus renewable energy into the natural gas network or the power grid.

- To optimize a system that is subject to high constraints with regard to electrical power supply and implement several technological elements.

| Markets

- Hydrogen mobility

- Power to Gas

- Energy storage (wind farm)

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- McLyzer 0.5 MW (250 kg per day)

- McStore 100 kg per day

Learn more about the solutions in the section: “Equipment & Services”.

| Key points

- Location: Berlin (Germany)

- Commissioning: 2014

Gallery

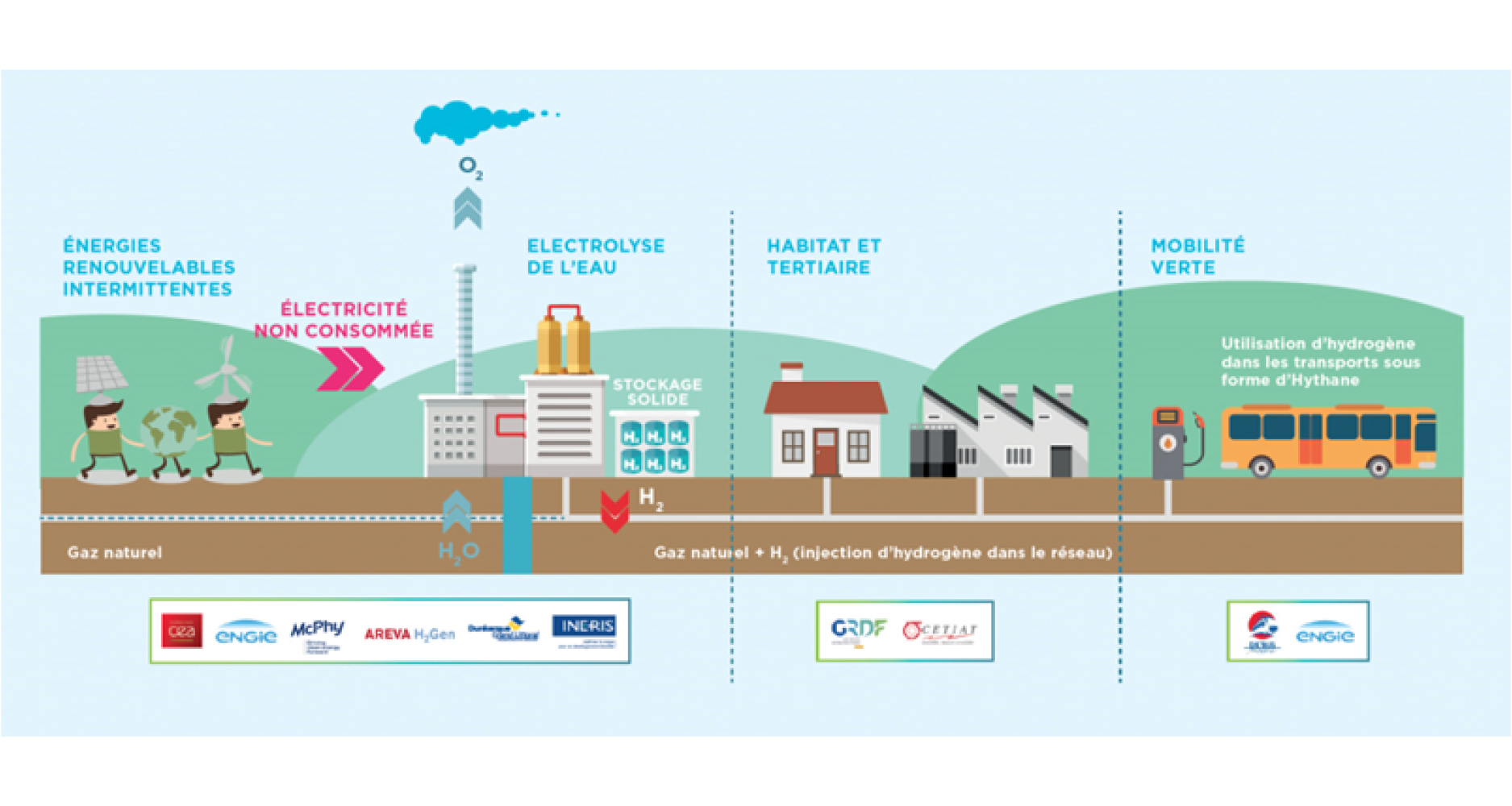

GRHYD: McPhy equips the first Power to Gas demonstrator in France

• The first Power-to-Gas demonstrator in France

• 11 leading partners in zero-carbon energy

• 5 years of study, authorization and demonstration

• 100 homes and the health center boiler supplied by a new gas made up of hydrogen and natural gas

• McPhy provided a McStore solid storage solution to the GRHYD project

The objective of the project is to evaluate and validate the technical and economic relevance of home energy solutions using a natural gas and hydrogen component.

Launched in 2014, GRHYD is a project to inject hydrogen into the territory’s natural gas distribution network in order to meet the needs of the residents of the new neighborhood of Cappelle-la-Grand in terms of heating, hot water and cooking. Approximately 100 homes are supplied with a mixture of hydrogen and natural gas, in variable proportions of hydrogen and less than 20% by volume. The objective of the project is to evaluate and validate the technical and economic relevance of home energy solutions using a natural gas and hydrogen component.

GRHYD is coordinated by ENGIE in association with 10 other partners, it’s supported by the government as part of the Future Investment Program operated by ADEME and labeled by the Tenerrdis competitiveness cluster.

As the first Power to Gas demonstrator in France, GRHYD represents a large-scale demonstration stage, which is the necessary transition between the previous experiments and the ambition of future industrialization of this process.

Inaugurated in 2018, the experimentation ended in 2020.

| Markets

- Power to Gas

- Hydrogen for local communities

- Energy storage

- Research and innovation

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- McStore (McPhy stopped the commercialization of its solid storage solution in December 2018)

Learn more about the solutions in the section: “Equipment & Services”.

| Customer

- ENGIE

- Location: Cappelle-la-Grande, France

- Launch date: 2014, inauguration in 2018, end of experimentation in 2020

Read the press release