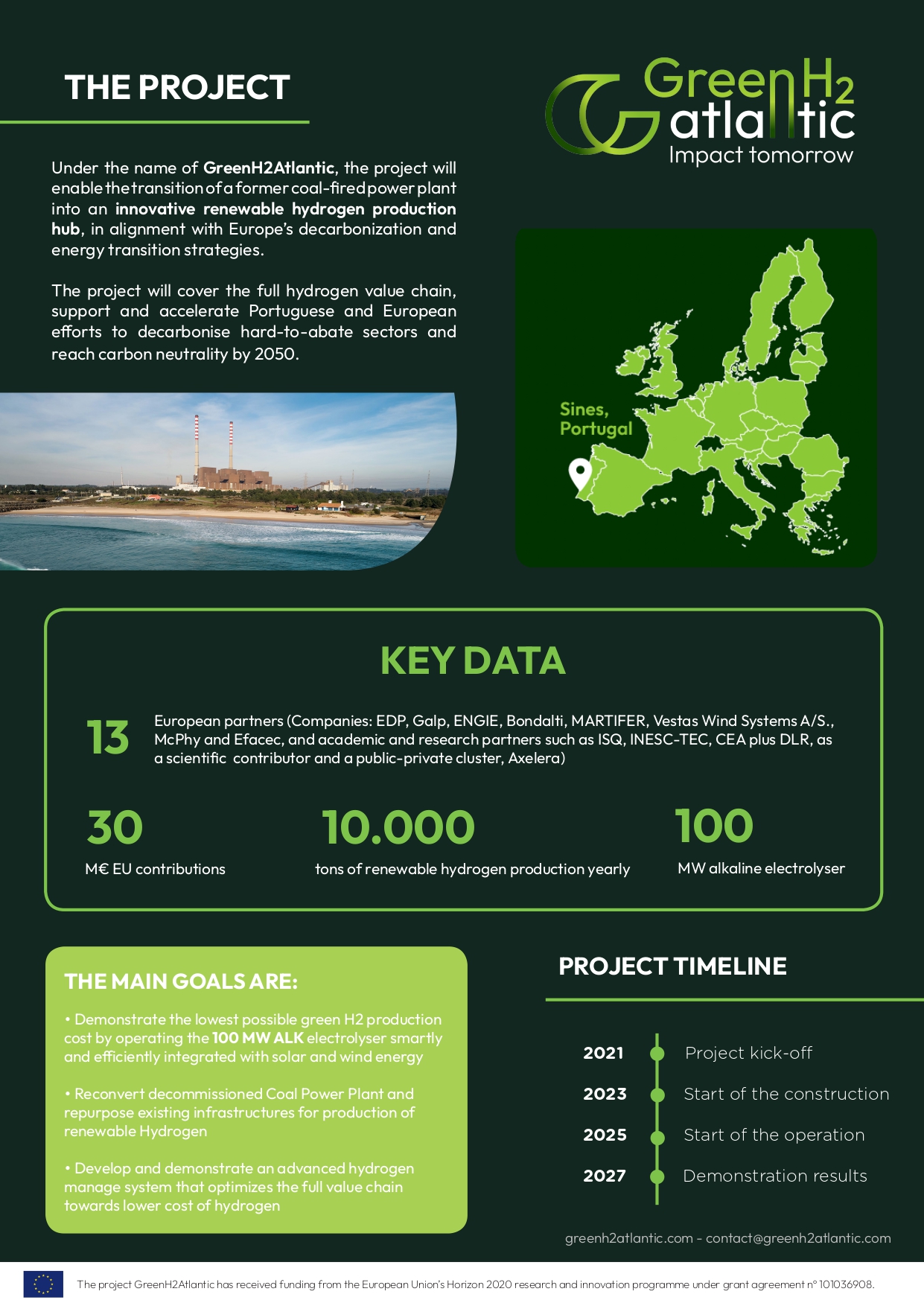

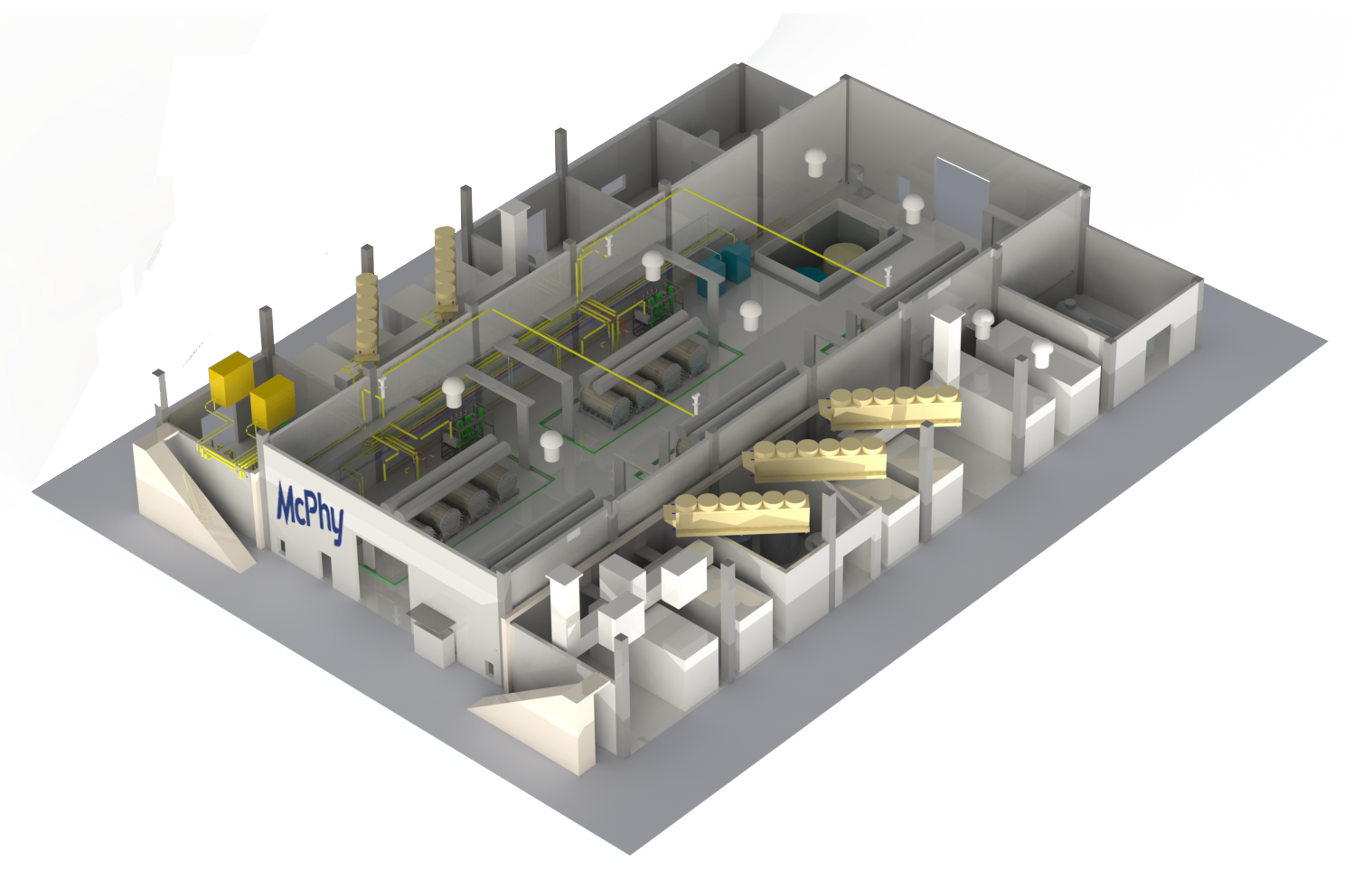

The GreenH2Atlantic project consists in a 100 MW flexible green hydrogen production to be installed in Sines, Portugal, to supply multiple end-uses. The consortium developing this project is composed of 13 European companies from the full value chain and of research partners, to which McPhy will bring the electrolysis technological brick.

• Electrolysis: 100 MW electrolysis platform

• Innovative technology “Augmented McLyzer”: scalable and fast-cycling

• 41 tons of green hydrogen to be produced per day, 10 000 tons yearly and 80 kilotons of Co2 emissions avoided / year (equivalent of 18 700 passenger vehicles driven in one year)

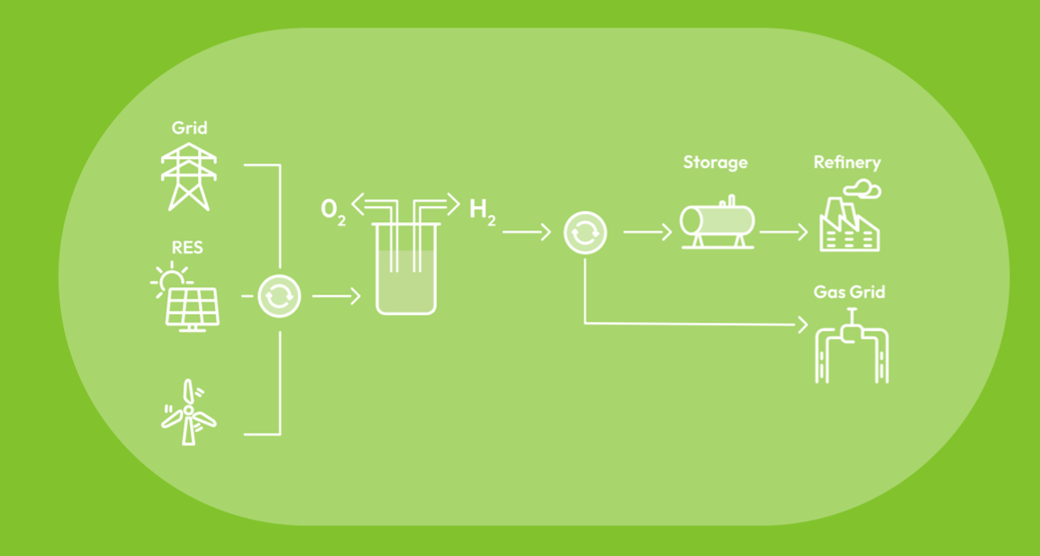

• Industrial & energy uses: refinery and injection in the gas grid

• Construction expected start: 2024 | Operation expected start: by the end of 2026

With the creation of a ‘hydrogen valley’, GreenH2Atlantic will significantly contribute to the sustainability goals of the region and Portugal, providing an important contribution to the European energy roadmap.

Under the name GreenH2Atlantic, a consortium of 13 companies and research partners are selected by the European Commission as part of the Green Deal to develop a renewable hydrogen production hub at 100 MW scale in Sines, Portugal.

The consortium supporting this project includes McPhy and companies such as EDP, Galp, ENGIE, Bondalti, Martifer, Vestas Systems A/S and Efacec, and academic and research partners such as ISQ, INESC-TEC, DLR and CEA, in addition to a public-private cluster, Axelera.

GreenH2Atlantic was one of the three projects selected by the Horizon 2020 – Green Deal Call to demonstrate the viability of green hydrogen production on an unprecedented scale.

The 30 million euros grant will help to finance the construction of the hydrogen plant, located in the coal-fired power plant area in Sines. The construction should start in 2024 and operation is expected to begin in 2026, subject to securing the necessary authorizations by the authorities.

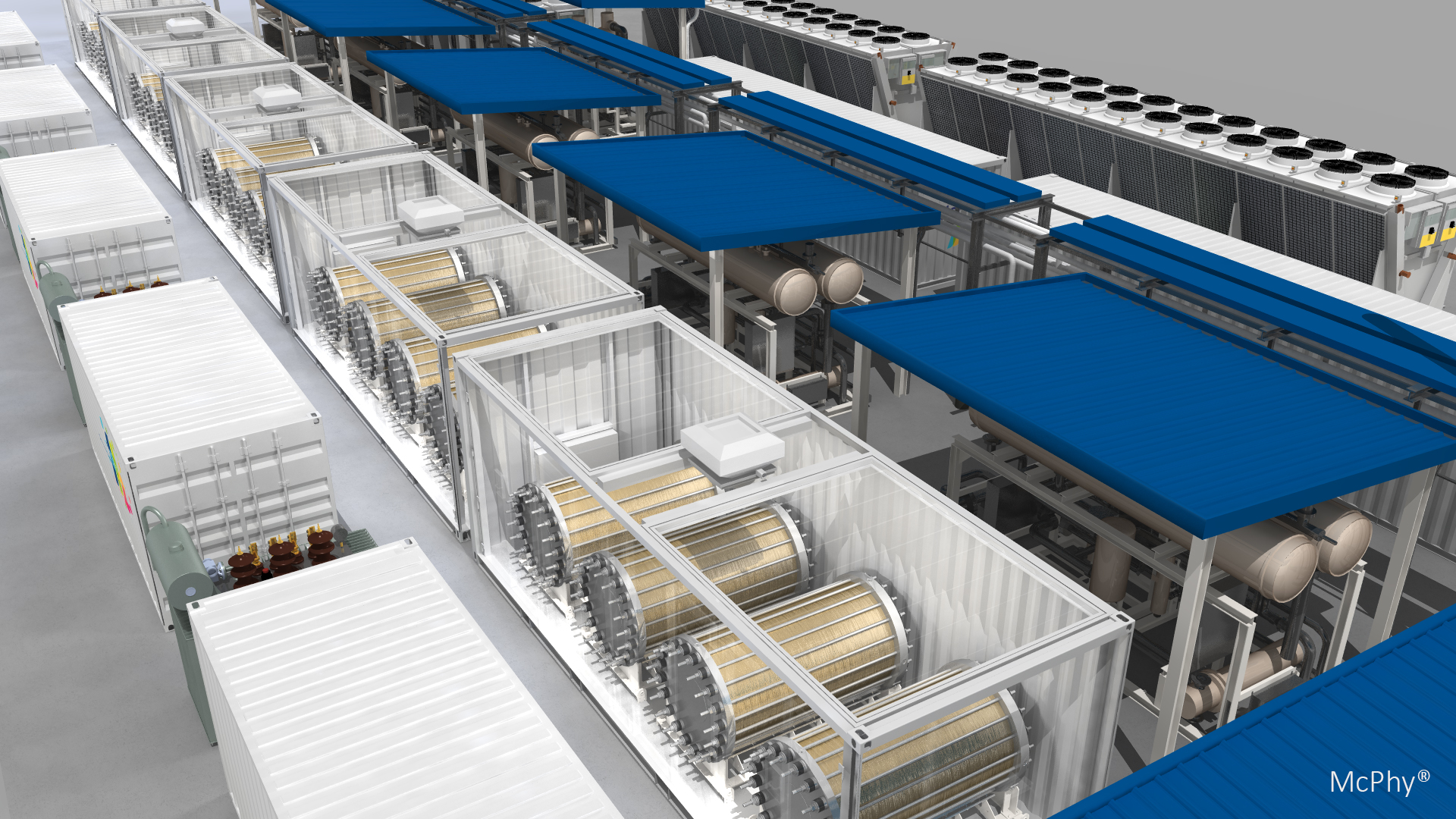

McPhy has been selected as preferred partner, with its innovative electrolysis technology “Augmented McLyzer” which will convert green electricity by electrolysis into more than 41 tons of clean hydrogen per day. This 100 MW electrolyzer will be composed of innovative, scalable and fast-cycling 16 MW modules designed, manufactured and integrated by McPhy. The electrolysis platform is to supply low-carbon hydrogen for industrial (refinery) and energy (injection in the gas grid) uses, upscaling the link between renewables and industry, mobility and energy applications.

Low-carbon hydrogen is expected to become one of the pillars of economic growth, for it is a decisive energy vector in the decarbonization process for the main sectors of the economy.

This project will enable the transition of a former coal-fired power plant into an innovative renewable hydrogen production hub and create a ‘hydrogen valley’ centered in Sines. GreenH2Atlantic will significantly contribute to the sustainability goals of the region and Portugal, providing an important contribution to Europe’s decarbonization and energy transition strategies.

Recently, in December 2022, The GreenH2Atlantic project, has been granted the PIN (Potential National Interest) status.

Funded by the European Union’s Horizon 2020 research and innovation program

The project GreenH2Atlantic has received funding from the European Union’s Horizon 2020 research and innovation program under grant agreement nº 101036908.

| Markets

- Industry

- Energy

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- “Augmented McLyzer” technology: 100 MW electrolysis platform

Learn more about the solutions in the section: “Equipment & Services”.

| Customer

- European Commission as part of the Green Deal

- Location: Sines, Portugal

- Construction expected start: 2024 | Operation expected start: end of 2026

- Project website : www.greenh2atlantic.com

- https://www.greenh2atlantic.com/partners/mcphy

Gallery

A multimodal hydrogen ecosystem at the heart of the Auxerrois territory

• 1 MW of electrolysis

• 1 hydrogen station: 400 kg of green hydrogen produced per day and 2,200 tons of CO2 avoided per year

• Supply of 5 buses in the urban area of Auxerre (in due course light and heavy vehicles)

• Auxerre, France | Contract: 2020, inauguration in autumn 2021

Today the largest green hydrogen production and distribution site in France.

Inaugurated in October 2021, the AuxHYGen station in Auxerre is today the largest green hydrogen production and distribution site in France.

McPhy supplies to Hynamics the hydrogen equipment for the AuxHYGen project: a 1 megawatt-capacity electrolyzer and distribution station. This dual technology will allow the station to produce and distribute up to 400 kg of green hydrogen per day to first supply a fleet of 5 buses, and thus avoid the release into the atmosphere of 2,200 tons of CO2 per day in a year.

This project begins the development of a real multimodal hydrogen ecosystem in the Auxerrois region. The municipality, supported by ADEME, aims to triple the production capacities of the AuxHYGen station by 2025. [download project press kit | FR]

To date, it supplies 5 buses in the urban area of Auxerre, but aims to supply hydrogen to other modes of transport: light vehicles, trucks and even trains.

By helping to improve air quality, this zero-emission mobility project is an important step in the energy transition and fight against climate change of the region.

ADEME (Agence de la Transition Écologique) is a partner of this project

This project has received funding from the Fuel Cells and Hydrogen 2 Joint Undertaking program within the framework of the European Union’s “Horizon 2020” research and innovation program under grant agreement n ° 779563.

| Markets

- Hydrogen mobility

- H2 in the territories

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- 1 MW of alkaline electrolysis

- 1 station with a capacity of 400 kg / day

Learn more about the solutions in the section: “Equipment & Services”.

| Customer

- Hynamics

- Location: Auxerre, France

- Commissioning: inauguration fall 2021

Gallery

The first high-capacity hydrogen station in Strasbourg

• 1 Dual Pressure refill station 350-750 bar

• 700 kg of green hydrogen distributed per day

• 1 refueling interface for pressurized hydrogen cylinders (“tube trailers”)

• Innovative project for low-carbon mobility

• Strasbourg, France | Contract: 2021, commissioning: end of 2022

The R-Hynoca project illustrates the complementarity of the different green hydrogen production and distribution methods.

The R-Hynoca project led by the R-GDS group aims to decarbonize mobility by installing a high-capacity hydrogen station to supply its R-ENR production site in Strasbourg. The facility will produce carbon-neutral green hydrogen from local biomass (Haffner solution). This hydrogen will be recovered as a fuel for low-carbon mobility and as a resource for industry.

McPhy will supply a dual pressure station (350-750 bar) equipped with two terminals for recharging all types of hydrogen mobility: a “Dual Pressure” terminal, for light vehicles 700 bar and 350 bar and a “Hi-Flow” terminal for buses and heavy goods vehicles.

This large-capacity station will deliver 700 kg of green hydrogen per day, allowing approximately the daily recharging a fleet of 30 buses, or 70 light commercial vehicles, or 150 light vehicles.

McPhy will also equip the production site with a refueling point for pressurized hydrogen cylinders (“tube trailers”) to be transported and used for mobility or industrial applications away from the hydrogen production site.

Innovative and scalable, the modular design of the R-Hynoca project will enable the distribution capacity to be increased at the same rate as the applications will be deployed on the territory.

With this new reference, McPhy stands out among the leaders in hydrogen mobility.

Funded by FCH-JU & European Union, Hydrogen Europe and Hydrogen Europe Research

The R-Hynoca project is funded by the public-private partnership FCH-JU3 under the H2ME2 program and grant agreement No. 700339. This joint venture is supported by the European Union’s Horizon 2020 research and innovation program, Hydrogen Europe and Hydrogen Research.

| Markets

- Hydrogen mobility

- H2 in the territories

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- 1 “Dual Pressure” refill station 350-750 bar high capacity 700 kg / day

- 1 “Hi-Flow” station for buses and trucks

- 1 refueling interface for pressurized hydrogen cylinders “tube trailers”

Learn more about the solutions in the section: “Equipment & Services”.

| Customer

- R-GDS

- Location: Strasbourg, France

- Contract: 2021

Gallery

The world’s first multi-megawatt hydrogen power plant

• 16 MW of high-power electrolysis

• 860 tons of green hydrogen (power supply: photovoltaic) produced and 39,000 tons of CO2 avoided per year

• First “outdoor” configuration of McPhy alkaline electrolysis

• Guyana, France | Contract: 2021, deployment 2024

The CEOG project demonstrates McPhy’s technological expertise and ability to help scale up hydrogen solutions.

The CEOG West Guyana Power Plant project, led by Meridiam, HDF and SARA, is the world’s largest power plant project combining photovoltaic energy and massive 128 MWh storage, mainly in form of hydrogen.

McPhy will supply the 16 MW hydrogen production platform, which will be commissioned in 2024. It will be equipped with the innovative “Augmented McLyzer” technology: a unique combination of high-pressure alkaline electrolysis (30 bar) and high current density electrodes. Powered from water and green electricity produced by the photovoltaic park, this platform will allow the production of nearly 860 tons of green hydrogen per year and will prevent the emission of 39,000 tons of CO2 per year compared to a fossil power plant (1).

Combining both a photovoltaic solar park, a multi-megawatt electrolyzer, a hydrogen storage unit and high-power fuel cells, CEOG plant will produce hydrogen that will be stored under pressure in tanks. This production will ensure the supply of electricity to 10,000 homes in Guyana, at a competitive cost compared to thermal power plants in the region, and without emitting pollution.

This world first represents a decisive milestone for the industrialization of the hydrogen sector.

(1) ADEME study: : https://www.guyane.ademe.fr/sites/default/files/notes-emissions-gaz-effet-serre-secteur-energetique-guyane.pdf ; integrating CEOG’s carbon intensity of 0.136 kg CO2 eq/kWh; emission factor of the thermal kWh of the Guyanese coastline of 0.915 kg CO2 eq/kWh.

Project in collaboration with partners Meridiam, SARA and HDF

| Markets

- Industry

- Energy

- H2 in the territories

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- 1 “Augmented McLyzer” 16MW electrolyzer

- “Outdoor” configuration of McPhy alkaline electrolysis

Learn more about the solutions in the section: “Equipment & Services”.

| Customer

- GEOG project

- Location: Guyana, France

- Commissioning: 2024

Gallery

A first hydrogen production and distribution system to be implemented in an airport area

Equipped with a complete zero-carbon hydrogen chain, the HYPORT project meets new mobility and logistics needs of Toulouse-Blagnac airport.

McPhy will equip Toulouse-Blagnac airport with two hydrogen stations: 1 Dual Pressure high-capacity station: 400 kg/d to be deployed in public zone and 1 Starter Kit (20 kg/d at 350 bar), in private restricted zone for airport services.

• A 1 MW alkaline electrolysis platform will complete the equipment to produce green hydrogen on-site

• Toulouse, France | Contract: 2020, deployment end of 2021

McPhy and HYPORT contribute to decarbonize airport areas

McPhy will be a key partner of HYPORT to equip Toulouse-Blagnac airport with a complete zero-carbon hydrogen chain.

The equipment will me made of two hydrogen stations set up in the immediate surroundings of the airport’s runways and roadways. An electrolyzer will also be deployed, with a capacity of 400 kg per day, or the equivalent of 1 MW. It will supply the stations and the nearby industrial sites in green hydrogen.

To meet the airport area needs, a first station “Strater Kit” will be set up in a private restricted zone for airport services.

Equipped with “Dual Pressure” configuration (two distribution pressures: 350 and 700 bar) the second station will be deployed in a public zone and enable all types of vehicles (buses, light commercial vehicles, captive fleets, large goods vehicles, etc.) to be refueled with hydrogen.

This complete zero-carbon hydrogen production and distribution solution, scheduled for the end of 2021, will power nearly 200 vehicles, including a fleet of 4 buses operated by Transdev to transport passengers within the airport.

Beyond its pioneering nature, this project aims to support the deployment of hydrogen as a solution for the energy transition in the airport and aeronautical sector.

Combining mobility, logistics and industrial uses, airports constitute real energy hubs, ideal for the development of hydrogen-based ecosystems. Airport areas are contributing to the so-called “zero-emission” strategies and to fight against climate change.

Project supported by the Région Occitanie & ADEME

This project is supported by the Région Occitanie, the ADEME (the agency for ecological transition) and the JIVE 2 project, co-financed by the FCH JU.

| Markets

- Hydrogen Mobility

- Hydrogen for local communities

Learn more about the H2 applications in the section: “Industry”.

| Equipment & Services

- 1 MW alkaline electrolysis platform

- 1 Dual Pressure high-capacity station: 400 kg/d

- 1 Starter Kit (20 kg/d at 350 bar)

Learn more about the solutions in the section: “Equipment & Services”.

| Customer

- HYPORT

- Location: Toulouse, France

- Commissioning: 2021

Gallery

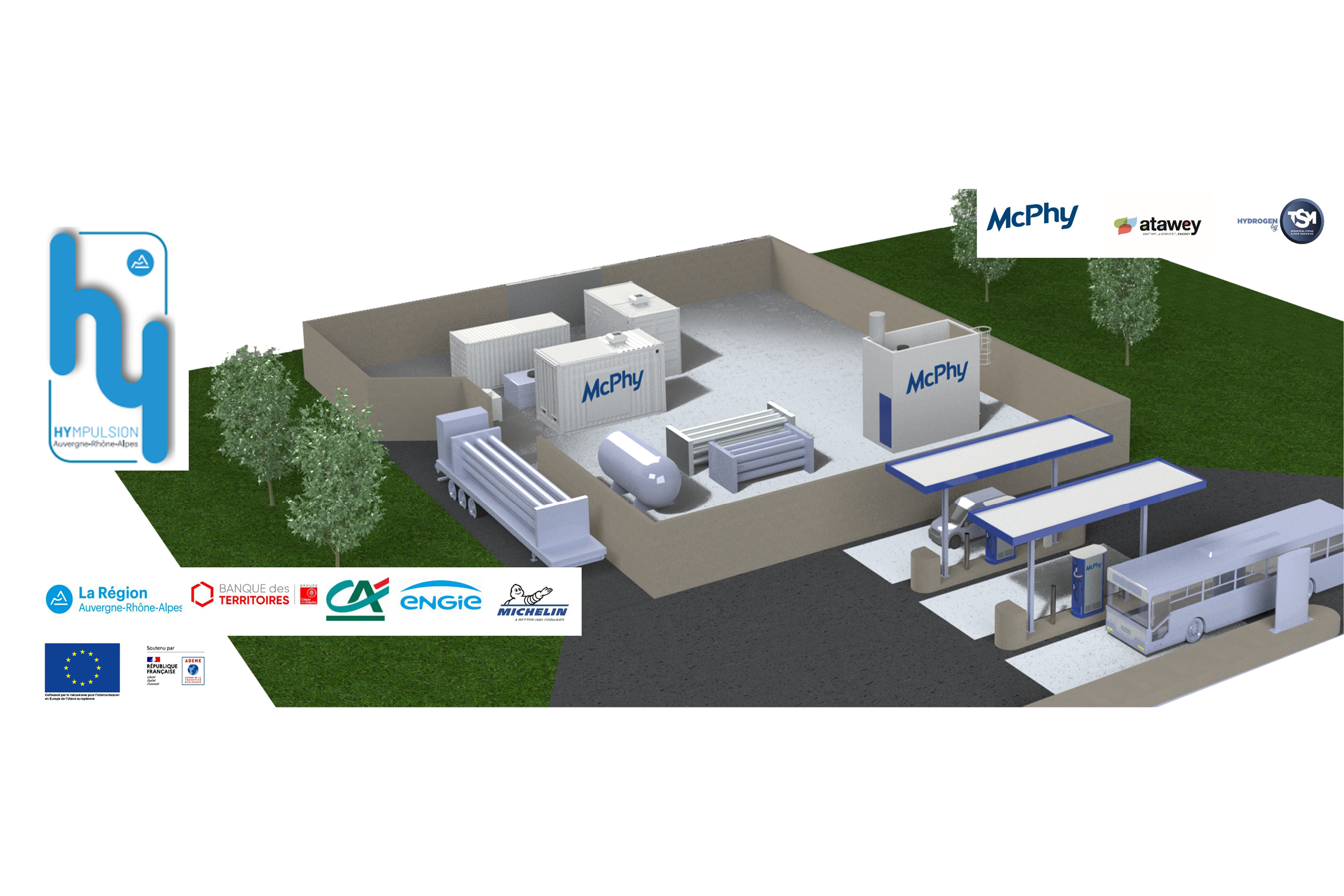

The largest hydrogen mobility deployment project in France

Zero Emission Valley is one of the most ambitious zero-emission mobility project in Europe

• After having equipped the 1st station of the ZEV project (Chambéry) with a 40kg/day electrolyzer

• McPhy will supply 5 hydrogen stations 400/800 kg / day + 4 MW electrolysis*

• Auvergne Rhône-Alpes Region, France | Contract : June 2020

Zero Emission Valley embodies the energy transition at regional level

Initiated by the Auvergne-Rhône-Alpes Regional council, deployed by Hympulsion and supported by the European Union, the Zero Emission Valley (ZEV) project stands out by its scale and its innovative nature.

The plan aims at deploying, before the end of 2023, 1,200 fuel cell vehicles, 20 hydrogen stations, including several with electrolyzers to produce hydrogen from renewable electricity without emitting CO2. This project aims to make Auvergne-Rhône-Alpes the pioneering region for hydrogen mobility in France and one of the first carbon-neutral territories at the European level, while helping to create profitable models that can be replicated on a European scale.

The MAT consortium, made up of McPhy, Atawey and TSM, is selected to supply, on the basis of a framework contract, 14 hydrogen stations, several of which equipped with electrolyzers.

Within the consortium, McPhy technologies will equip 5 high-capacity hydrogen stations (McFilling 400/800 kg / day) and several McLyzer electrolyzers*.

With more than 620,000 liters of fossil fuels replaced and more than 1,500 tons of CO2 emissions avoided each year, this project will make it possible to respond to climate challenges, such as those set by the Green Pact for Europe, which aims to make Europe climate neutral by 2050, while demonstrating that economic development, wealth creation and preservation of the environment can be compatible.

Supported by the European Union & ADEME

This project is financed by the Auvergne-Rhône-Alpes Region of council, ADEME and the European program CEF Transport.

| Markets

- Hydrogen Mobility

- Hydrogen for local communities

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- 5 stations McFilling 400/800 kg / day*

- 4 MW of electrolysis*

Learn more about the solutions in the section: “Equipment & Services”.

| Customer

- Hympulsion

- Location: AURA region, France

Read the press release

* Among them: 2 HRS and 4 MW ELY are conditional part of the ZEV framework contract [signed on 18 June 2020]

Gallery

McPhy will equip the largest zero-carbon hydrogen production unit in Europe

• Djewels: key project to establish zero-carbon hydrogen competitiveness at large-scale

• 20 MW: 3,000 tons of zero-carbon H2 / year and 27,000 tons of Co2 emissions avoided / year

• Decarbonation of industrial processes in the heart of a chemical park

• Delfzijl, The Netherlands | Contract: 2020

This project will enable to scale-up and industrialize clean hydrogen production technologies

Djewels is a project is a front-runner among hydrogen initiatives with the objective of reducing carbon emissions. Initiated by Nouryon, a leading specialty chemical company, and Gasunie, a gas infrastructure company; this project will enable to scale-up and industrialize clean hydrogen production technologies to lower their costs and boost the rise of a clean, secure and cost-competitive hydrogen ecosystem.

The innovative technology “Augmented McLyzer” by McPhy will be the cornerstone of the project and will enable the implementation of the project value chain:

- 20 MW electrolysis platform developed by McPhy: to convert electricity from renewable sources into zero-carbon hydrogen

- Zero-carbon hydrogen will be transported from the point of production to the point of consumption

- Zero-carbon hydrogen will enable the production of “e-methanol” (renewable methanol)

Funded by the FCH-JU & Waddenfonds

The proposed clean hydrogen project will be funded by an €11m EU grant from the Fuel Cells and Hydrogen Joint Undertaking (FCH-JU) as well as an additional €5m in subsidies from Waddenfonds, a fund that invests in projects in the Netherlands.

| Markets

- Industrial hydrogen

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- “Augmented McLyzer” 20 MW electrolysis platform

Learn more about the solutions in the section: “Equipment & Services”.

| Customer

- Nouryon, Gasunie

- Location: Delfzijl, The Netherlands

- Contract: 2020

Read the press release

First hydrogen station connected to an electrolyzer

dedicated to public transport in France

A pioneering zero emissions mobility project for heavy transport in France. The “Syndicat mixte des transports Artois-Gohelle” (SMT AG) is launching the first 100% hydrogen bus line and its dedicated station, the precursors of the “zero emissions mobility” revolution, which is spreading in France, Europe and worldwide.

• Fleet of 6 buses powered by a 200 kg/day station connected to 0.5 MW of electrolysis

• Design: Compression redundancy, two distribution units

• 0.5 MW of electrolysis divided into three containers

• Shared Balance of Plant (BOP): support components and auxiliary systems

• Aerial piping system

• Béthune, France | Commissioning: 2019

McPhy technologies equip the entire production and distribution chain of clean hydrogen.

McPhy was selected for the project of the first station for hydrogen bus refueling in France. It will provide clean fuel for the six hydrogen buses that will be deployed on the new High Service Level Bus line that will connect Bruay-La-Buissière to Auchel (Hauts-de-France Region).

Our McLyzer and McFilling technologies are used in this innovative project. Clean hydrogen will thus be produced on site by electrolysis, (from guaranteed renewable electricity from France), before being distributed by the station. After fifteen minutes of recharging, the buses will have a range of more than 300 km.

In its current configuration, the McPhy solution can produce and deliver up to 200 kg of clean hydrogen per day. Its capacity can be increased by 30%, without modifying the total surface area of the installation, if the future needs of the SMT AG require it.

“With our technologies and products, we are contributing to this first-of-its-kind in France, which enables us to set up the first McPhy station for hydrogen buses in the Hauts-de-France region. With state-of-the-art research and innovation and a leading industrial infrastructure, McPhy brings its expertise in hydrogen production and distribution. Our McLyzer electrolyzer will produce on site and from renewable electricity of certified French origin supplied by ENGIE, the clean hydrogen for a high-capacity McFilling hydrogen refueling station with a high service rate. The public transport sector is in the midst of a revolution. By opting for hydrogen mobility, the SMT AG is combining passenger comfort and service continuity while helping reduce atmospheric pollution and improve public health.” | Pascal Mauberger, Chairman and CEO of McPhy

| Markets

- Hydrogen mobility

- H2 in the territories

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- McLyzer 100-30

- McFilling 200-350

Learn more about the solutions in the section: “Equipment & Services”.

| Client

- Engie GNVert

- Location: Houdain (France)

- Commissioning: 2019

Read the press release

Gallery

Photo credit: ENGIE Cofely – Photographer Arnaud Février

Development of the hydrogen infrastructure of the metropolis of Dijon

• Dijon Métropole is implementing a complete zero-emission hydrogen ecosystem

• McPhy will supply two stations with a capacity of 400 kg of hydrogen per day each, connected to a 1 MW high-power electrolyzer

• Dijon, France | Contract : July 2020

Four distribution terminals for both heavy and light vehicles will thus be available to supply the zero-emission vehicles of the collectivity and its partners. This fleet of hydrogen vehicles will initially be made up of 27 buses, 9 garbage trucks and around 15 light vehicles. The project is expected to reach a total of 200 buses, 50 garbage trucks and 250 light vehicles by 2030.

This project stands out for the positive energy loop it will create in the heart of the Dijon metropolitan area

This project stands out for the positive energy loop it will create in the heart of the Dijon metropolitan area. The electrolyzer connected to produce hydrogen on site will be powered 90% by electricity from a household waste incinerator and the remaining 10% will come from locally produced renewable energies. Consequently, the “Dijon Nord” project will enable the recovery of so-called “fatal” electricity, which would have been lost if it had not been used to power this ecosystem, and avoid nearly 2,500 tons of CO2 emissions per year.

McPhy will supply two McFilling hydrogen stations, one offering a filling pressure of 350 bar and the other offering a “Dual Pressure” configuration (350 and 700 bar), for a total daily potential of 800 kg of hydrogen delivered. Interfaced with the hydrogen stations, the McLyzer electrolyzer will have a production capacity equivalent to 1 MW of high-power electrolysis, ensuring optimal performance and energy efficiency to complete this hydrogen production and distribution ecosystem.

Supported by ADEME

The “Dijon Nord” project has received support and co-financing from the French Environment and Energy Management Agency (ADEME).

| Markets

- Hydrogen mobility

- H2 for local communities

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- 2 McFilling 400 kg of hydrogen / day each

- McLyzer 200-30 (1 MW)

Learn more about the solutions in the section: “Equipment & Services”.

| Customer

- Rougeot Energie

- Location: Dijon, France

- Commissioning: 2021

Read the press release

Hydrogen platform: heading for zero-carbon mobility

• McPhy installed a 2 MW electrolysis platform, producing over 300 tons of zero-carbon hydrogen from renewable energy per year

• The equipment supplies the headquarters of the Group and a commercial area with electricity and heating, it will aslo refuel all types of vehicles with green hydrogen

• Rostock-Laage, Germany | Commissioning: 2020

McPhy equips the zero-carbon hydrogen production plant of the German engineering and cleantech company Apex Energy.

More than 300 tons of zero-carbon hydrogen per year are produced from renewable energy sources.

For this project, McPhy delivered and installed a 2 MW electrolysis platform (McLyzer 400-30), producing over 300 tons of zero-carbon hydrogen from renewable energy per year.

Based in Rostock-Laage, this zero-carbon hydrogen production platform is dedicated to supplying electricity and heating to the head office and a commercial area using a fuel cell.

Apex Energy’s plant represents an important milestone in the industrialization of the hydrogen sector and demonstrates the growing interest of manufacturers who are making a strategic shift towards low-carbon energy.

| Markets

- Industrial Hydrogen

- Hydrogen for local communities

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- McLyzer 400-30

Learn more about the solutions in the section: “Equipment & Services”.

| Customer

- Apex Energy

- Location: Rostock-Laage, Germany

- Commissioning: 2020

Read the press releases: