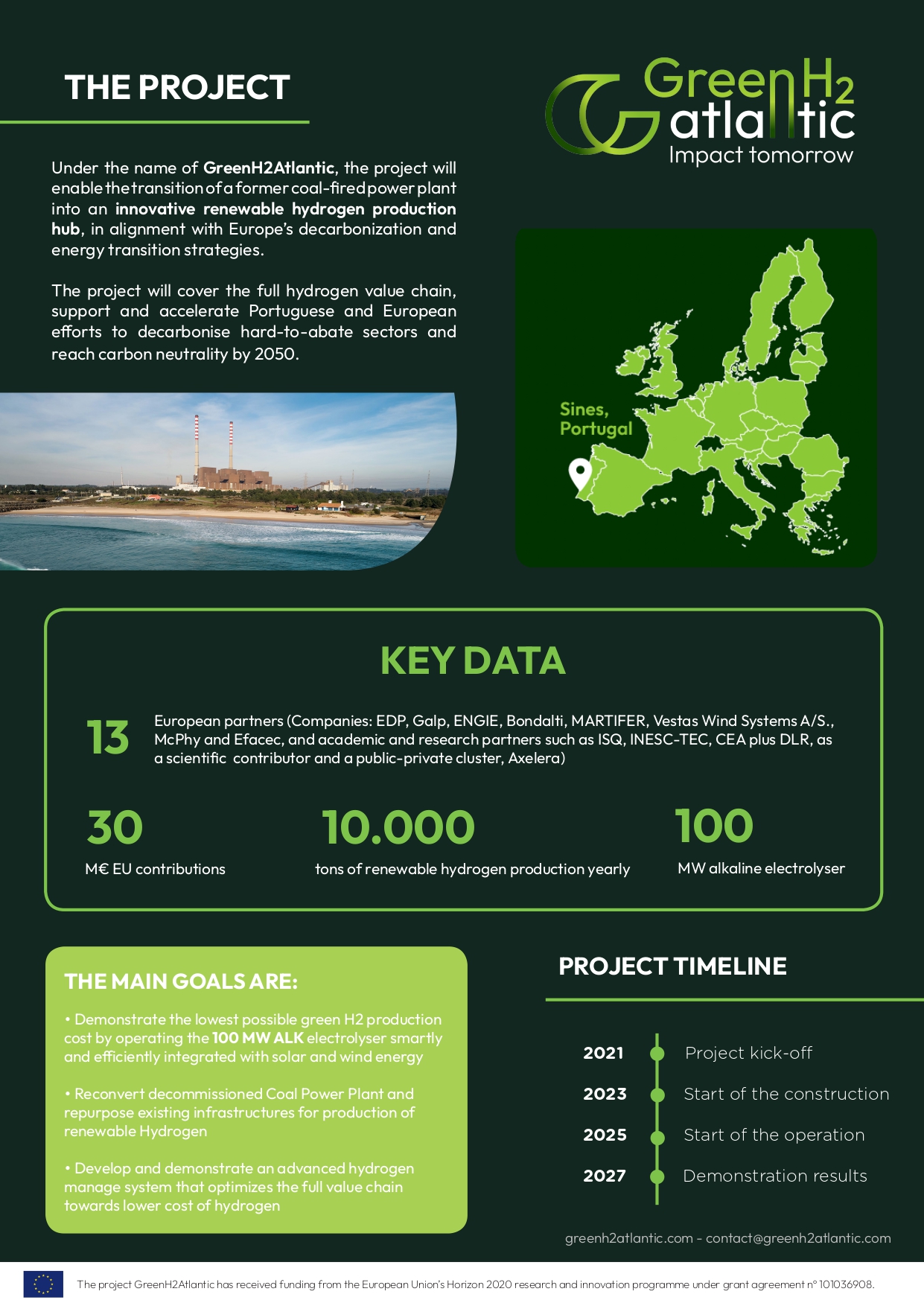

The GreenH2Atlantic project consists in a 100 MW flexible green hydrogen production to be installed in Sines, Portugal, to supply multiple end-uses. The consortium developing this project is composed of 13 European companies from the full value chain and of research partners, to which McPhy will bring the electrolysis technological brick.

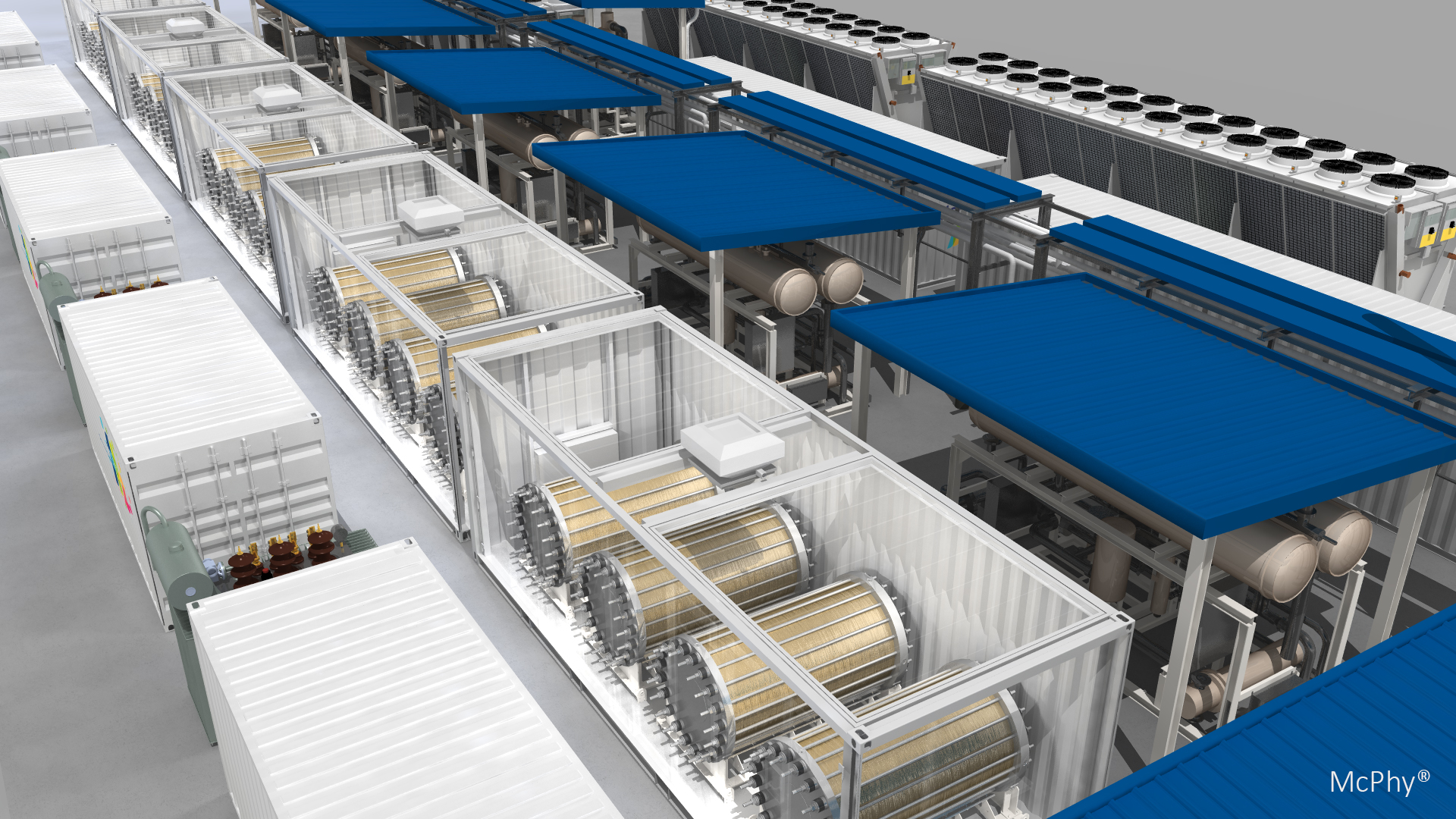

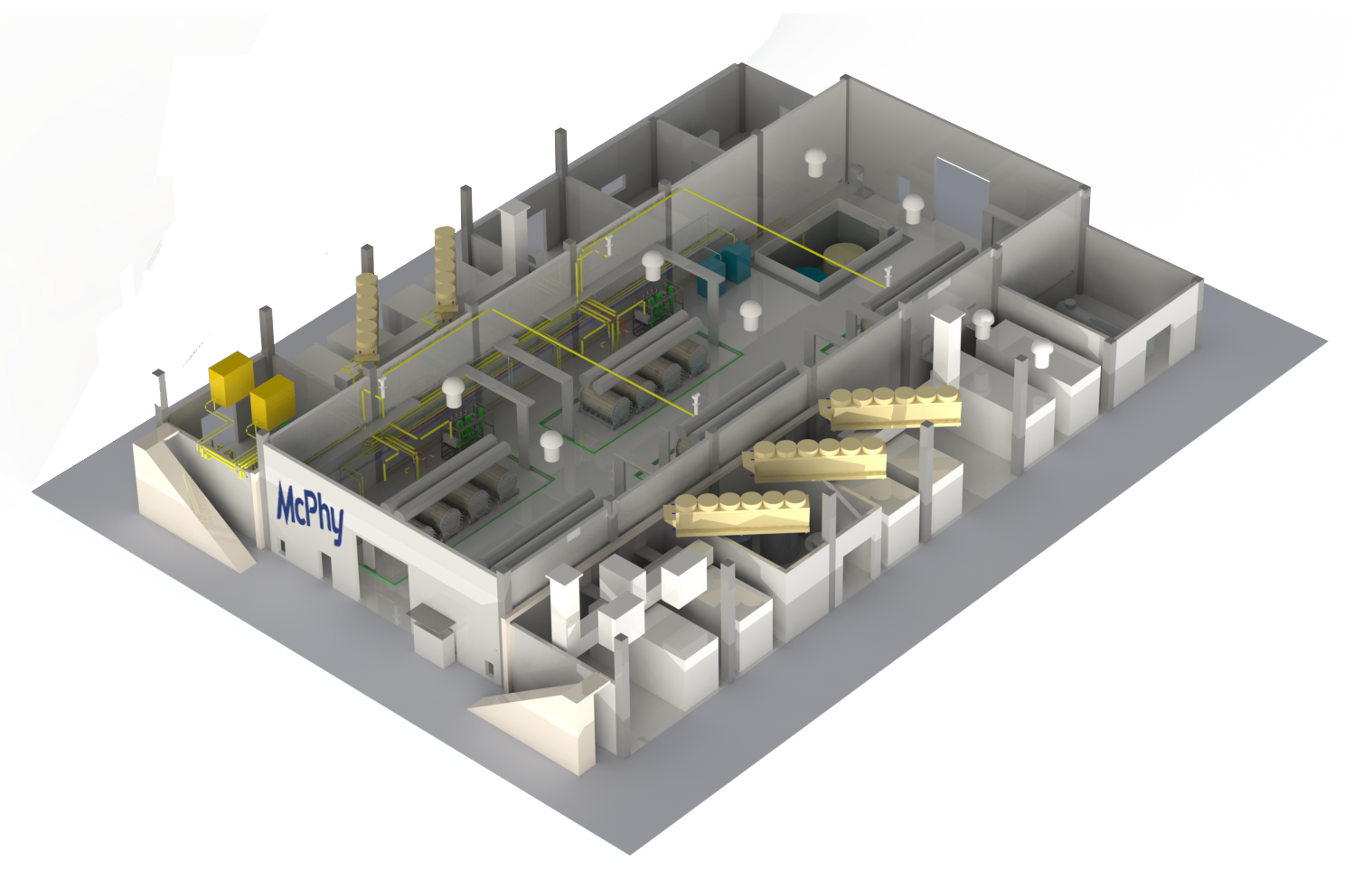

• Electrolysis: 100 MW electrolysis platform

• Innovative technology “Augmented McLyzer”: scalable and fast-cycling

• 41 tons of green hydrogen to be produced per day, 10 000 tons yearly and 80 kilotons of Co2 emissions avoided / year (equivalent of 18 700 passenger vehicles driven in one year)

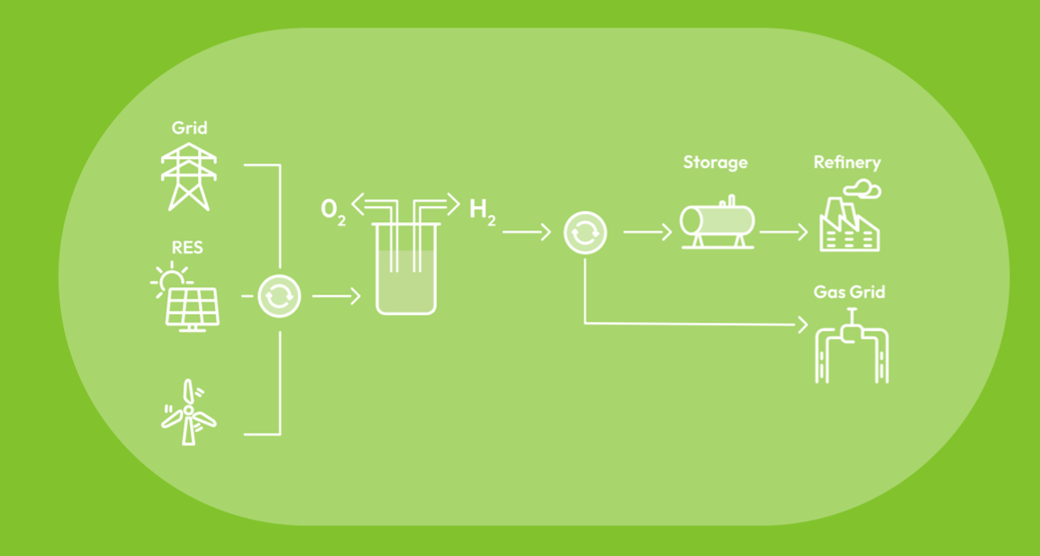

• Industrial & energy uses: refinery and injection in the gas grid

• Construction expected start: 2024 | Operation expected start: by the end of 2026

With the creation of a ‘hydrogen valley’, GreenH2Atlantic will significantly contribute to the sustainability goals of the region and Portugal, providing an important contribution to the European energy roadmap.

Under the name GreenH2Atlantic, a consortium of 13 companies and research partners are selected by the European Commission as part of the Green Deal to develop a renewable hydrogen production hub at 100 MW scale in Sines, Portugal.

The consortium supporting this project includes McPhy and companies such as EDP, Galp, ENGIE, Bondalti, Martifer, Vestas Systems A/S and Efacec, and academic and research partners such as ISQ, INESC-TEC, DLR and CEA, in addition to a public-private cluster, Axelera.

GreenH2Atlantic was one of the three projects selected by the Horizon 2020 – Green Deal Call to demonstrate the viability of green hydrogen production on an unprecedented scale.

The 30 million euros grant will help to finance the construction of the hydrogen plant, located in the coal-fired power plant area in Sines. The construction should start in 2024 and operation is expected to begin in 2026, subject to securing the necessary authorizations by the authorities.

McPhy has been selected as preferred partner, with its innovative electrolysis technology “Augmented McLyzer” which will convert green electricity by electrolysis into more than 41 tons of clean hydrogen per day. This 100 MW electrolyzer will be composed of innovative, scalable and fast-cycling 16 MW modules designed, manufactured and integrated by McPhy. The electrolysis platform is to supply low-carbon hydrogen for industrial (refinery) and energy (injection in the gas grid) uses, upscaling the link between renewables and industry, mobility and energy applications.

Low-carbon hydrogen is expected to become one of the pillars of economic growth, for it is a decisive energy vector in the decarbonization process for the main sectors of the economy.

This project will enable the transition of a former coal-fired power plant into an innovative renewable hydrogen production hub and create a ‘hydrogen valley’ centered in Sines. GreenH2Atlantic will significantly contribute to the sustainability goals of the region and Portugal, providing an important contribution to Europe’s decarbonization and energy transition strategies.

Recently, in December 2022, The GreenH2Atlantic project, has been granted the PIN (Potential National Interest) status.

Funded by the European Union’s Horizon 2020 research and innovation program

The project GreenH2Atlantic has received funding from the European Union’s Horizon 2020 research and innovation program under grant agreement nº 101036908.

| Markets

- Industry

- Energy

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- “Augmented McLyzer” technology: 100 MW electrolysis platform

Learn more about the solutions in the section: “Equipment & Services”.

| Customer

- European Commission as part of the Green Deal

- Location: Sines, Portugal

- Construction expected start: 2024 | Operation expected start: end of 2026

- Project website : www.greenh2atlantic.com

- https://www.greenh2atlantic.com/partners/mcphy

Gallery

The world’s first multi-megawatt hydrogen power plant

• 16 MW of high-power electrolysis

• 860 tons of green hydrogen (power supply: photovoltaic) produced and 39,000 tons of CO2 avoided per year

• First “outdoor” configuration of McPhy alkaline electrolysis

• Guyana, France | Contract: 2021, deployment 2024

The CEOG project demonstrates McPhy’s technological expertise and ability to help scale up hydrogen solutions.

The CEOG West Guyana Power Plant project, led by Meridiam, HDF and SARA, is the world’s largest power plant project combining photovoltaic energy and massive 128 MWh storage, mainly in form of hydrogen.

McPhy will supply the 16 MW hydrogen production platform, which will be commissioned in 2024. It will be equipped with the innovative “Augmented McLyzer” technology: a unique combination of high-pressure alkaline electrolysis (30 bar) and high current density electrodes. Powered from water and green electricity produced by the photovoltaic park, this platform will allow the production of nearly 860 tons of green hydrogen per year and will prevent the emission of 39,000 tons of CO2 per year compared to a fossil power plant (1).

Combining both a photovoltaic solar park, a multi-megawatt electrolyzer, a hydrogen storage unit and high-power fuel cells, CEOG plant will produce hydrogen that will be stored under pressure in tanks. This production will ensure the supply of electricity to 10,000 homes in Guyana, at a competitive cost compared to thermal power plants in the region, and without emitting pollution.

This world first represents a decisive milestone for the industrialization of the hydrogen sector.

(1) ADEME study: : https://www.guyane.ademe.fr/sites/default/files/notes-emissions-gaz-effet-serre-secteur-energetique-guyane.pdf ; integrating CEOG’s carbon intensity of 0.136 kg CO2 eq/kWh; emission factor of the thermal kWh of the Guyanese coastline of 0.915 kg CO2 eq/kWh.

Project in collaboration with partners Meridiam, SARA and HDF

| Markets

- Industry

- Energy

- H2 in the territories

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- 1 “Augmented McLyzer” 16MW electrolyzer

- “Outdoor” configuration of McPhy alkaline electrolysis

Learn more about the solutions in the section: “Equipment & Services”.

| Customer

- GEOG project

- Location: Guyana, France

- Commissioning: 2024

Gallery

McPhy will equip the largest zero-carbon hydrogen production unit in Europe

• Djewels: key project to establish zero-carbon hydrogen competitiveness at large-scale

• 20 MW: 3,000 tons of zero-carbon H2 / year and 27,000 tons of Co2 emissions avoided / year

• Decarbonation of industrial processes in the heart of a chemical park

• Delfzijl, The Netherlands | Contract: 2020

This project will enable to scale-up and industrialize clean hydrogen production technologies

Djewels is a project is a front-runner among hydrogen initiatives with the objective of reducing carbon emissions. Initiated by Nouryon, a leading specialty chemical company, and Gasunie, a gas infrastructure company; this project will enable to scale-up and industrialize clean hydrogen production technologies to lower their costs and boost the rise of a clean, secure and cost-competitive hydrogen ecosystem.

The innovative technology “Augmented McLyzer” by McPhy will be the cornerstone of the project and will enable the implementation of the project value chain:

- 20 MW electrolysis platform developed by McPhy: to convert electricity from renewable sources into zero-carbon hydrogen

- Zero-carbon hydrogen will be transported from the point of production to the point of consumption

- Zero-carbon hydrogen will enable the production of “e-methanol” (renewable methanol)

Funded by the FCH-JU & Waddenfonds

The proposed clean hydrogen project will be funded by an €11m EU grant from the Fuel Cells and Hydrogen Joint Undertaking (FCH-JU) as well as an additional €5m in subsidies from Waddenfonds, a fund that invests in projects in the Netherlands.

| Markets

- Industrial hydrogen

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- “Augmented McLyzer” 20 MW electrolysis platform

Learn more about the solutions in the section: “Equipment & Services”.

| Customer

- Nouryon, Gasunie

- Location: Delfzijl, The Netherlands

- Contract: 2020

Read the press release

Hydrogen platform: heading for zero-carbon mobility

• McPhy installed a 2 MW electrolysis platform, producing over 300 tons of zero-carbon hydrogen from renewable energy per year

• The equipment supplies the headquarters of the Group and a commercial area with electricity and heating, it will aslo refuel all types of vehicles with green hydrogen

• Rostock-Laage, Germany | Commissioning: 2020

McPhy equips the zero-carbon hydrogen production plant of the German engineering and cleantech company Apex Energy.

More than 300 tons of zero-carbon hydrogen per year are produced from renewable energy sources.

For this project, McPhy delivered and installed a 2 MW electrolysis platform (McLyzer 400-30), producing over 300 tons of zero-carbon hydrogen from renewable energy per year.

Based in Rostock-Laage, this zero-carbon hydrogen production platform is dedicated to supplying electricity and heating to the head office and a commercial area using a fuel cell.

Apex Energy’s plant represents an important milestone in the industrialization of the hydrogen sector and demonstrates the growing interest of manufacturers who are making a strategic shift towards low-carbon energy.

| Markets

- Industrial Hydrogen

- Hydrogen for local communities

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- McLyzer 400-30

Learn more about the solutions in the section: “Equipment & Services”.

| Customer

- Apex Energy

- Location: Rostock-Laage, Germany

- Commissioning: 2020

Read the press releases:

1 MW of electrolysis to support the valorization of the renewable energy surplus in Germany

• Contract with a leading energy company

• Very fast dynamic response, adapted to renewable energy variations

• Wyhlen, Germany | Commissioning: 2017

This project provides an efficient and competitive answer to the issues raised by renewable energies, which are intermittent in nature and need adapted storage and valorization solutions.

“This project will contribute to the development of renewable electricity sources in Germany, the world’s second largest renewable energy producer, by offering a competitive solution to valorize to production surplus”

McPhy has equipped in 2017 the site with a 1 MW zero-carbon hydrogen production plant and is supporting EnergieDienst in the valorization of this hydrogen in industry, zero-emission mobility or injection into gas networks.

| Markets

- Power to Gas

- Industrial hydrogen

- Energy storage (hydrolic power plant)

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- McLyzer 200-30

Learn more about the solutions in the section: “Equipment & Services”.

| Client

- EnergieDienst

- Location: Bade-Wurtemberg (Allemagne)

- Commissioning: end 2017

Read the press release

Since 2013, an industrial hydrogen production unit

• Precursor project of Power to Gas in Europe

• Electrolyzer plant and maintenance contract for the Audi’s e-gas plant

• Werlte, Germany | Commissioning: 2013

The 6 MW alkaline electrolyzer is a key component of e-gas power plant technology, making it possible to extract hydrogen from water using surplus electricity. Through its expertise, McPhy Energy’s subsidy in Wildau (Germany) has further optimized this technology ( today known as “Alcaline 2.0” electrolysis) and developed in-depth experience ensuring its integration into energy infrastructures such as electrical or natural gas networks.

The plant therefore uses surplus green electricity to produce hydrogen from water in three alkaline electrolyzers. The hydrogen is reacted with CO2 to produce synthetic methane, or Audi e-gas.

It is virtually identical to the fossil fuel and natural gas, and is distributed through an existing infrastructure, the German natural gas network, to CNG filling stations for Audi’s A3 g-tron series. Audi produces up to 1,000 metric tons of e-gas per year, chemically binding some 2,800 metric tons of CO2. This roughly corresponds to the amount that a forest of over 220,000 beech trees absorbs in one year. Water and oxygen are the only by-products.

| Markets

- Industrial hydrogen

- Power to Gas

- Hydrogen territories

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- 6 MW electrolysis solution

Learn more about the solutions in the section: “Equipment & Services”.

| Customer

- Audi

- Location: Werlte (Germany)

- Commissioning: 2013

Read the press release

Gallery

Production and storage of clean hydrogen for industrial processes

• Illustrates the potential of decarbonized hydrogen produced by electrolysis as a feedstock for industry

• Guaranteed industrial performance and energy independence while reducing the environmental footprint of the PUS

• Grenoble, France | Commissioning: June 2018

Since 2018, with three electrolyzers and two storage modules, McPhy offers a complete solution adapted to the significant increase in hydrogen requirements of the Utility Services Unit (PUS) located at the heart of the scientific cluster on the CEA Minatec site in Grenoble.

Guaranteeing industrial performance and energy independence while reducing the environmental footprint of the PUS.

As part of this industrial & mobility project, McPhy designed a production and storage unit offering a suitable response to the significant increase in hydrogen requirements of the Utilities Services Unit.

This production unit demonstrates the potential of zero-carbon hydrogen produced by electrolysis for industry. It is intended to supply hydrogen to CEA’s industrial processes and to the GEG (Gaz Électricité Grenoble) hydrogen station which powers the HyWay project (zero emissions mobility).

The hydrogen production unit is composed of three alkaline electrolyzers which will produce up to 150,000 m3 of hydrogen per year. The hydrogen produced is compressed at 200 bar in a gaseous form; and at 30 bar in a solid form via the McPhy hydrogen storage technology.

This installation is part of the HyWay project led by Tenerrdis.

The HYWAY project aims to promote, promote and validate the technical, economic and environmental relevance of the French model for deploying hydrogen mobility around captive fleets.

| Markets

- Industrial hydrogen

- Hydrogen mobility

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- 3 McLyzer 10-10

- 2 McStore

Learn more about the solutions in the section: “Equipment & Services”.

| Client

- Engie Cofely

- Location: CEA of Grenoble (France)

- Commissioning: June 2018

Read the press release