• First hydrogen station in the Paris region

• Starter Kit McFilling, capacity 20 kg / day at 350 bar

• Refueling 10 to 15 vehicles per day

• Paris, France | Commissioning: 2015

The City of Paris has made reducing air pollution a top priority. With this goal, as it innovates and plans for the future of its light utility vehicle fleet, the French capital has selected the Idex-McPhy Energy team to install and manage the hydrogen refueling station to be located in Ivry-sur-Seine.

This station was inaugurated during the COP21 (2015). This project is in line with both the ambitious mobility plan being adopted by the City of Paris as well as the objectives of combating pollution and global warming, which were reaffirmed during COP21.

McPhy designed, manufactured and integrated this hydrogen station capable of fueling up to 15 vehicles per day (McFilling 20-350) at a 350 bar dispensing pressure.

“By winning this call for tenders by France’s most important city with our partner, Idex, McPhy Energy has once again demonstrated the perfect alignment of its offering of modular refuelling stations with the needs for deploying soft hydrogen infrastructure that is easily integrated at the local level in major urban regions. We are particularly proud of being able to demonstrate in this way the relevance of hydrogen mobility as a means of reducing the emission of pollutants in the transportation sector during an event of such symbolic importance as the COP21”

| declared Pascal MAuberger, McPhy Energy’s Chairman and CEO.

McFilling 20-350 in Ivry-sur-Seine

| Markets

- Hydrogen mobility

- Hydrogen territories

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- McFilling 20-350

Learn more about the solutions in the section: “Equipment & Services”.

| Customer

- City of Paris | Operator: Idex

- Location: Ivry Sur Seine (France)

- Commissioning : 2015

Read the press release

Gallery

Since 2013, an industrial hydrogen production unit

• Precursor project of Power to Gas in Europe

• Electrolyzer plant and maintenance contract for the Audi’s e-gas plant

• Werlte, Germany | Commissioning: 2013

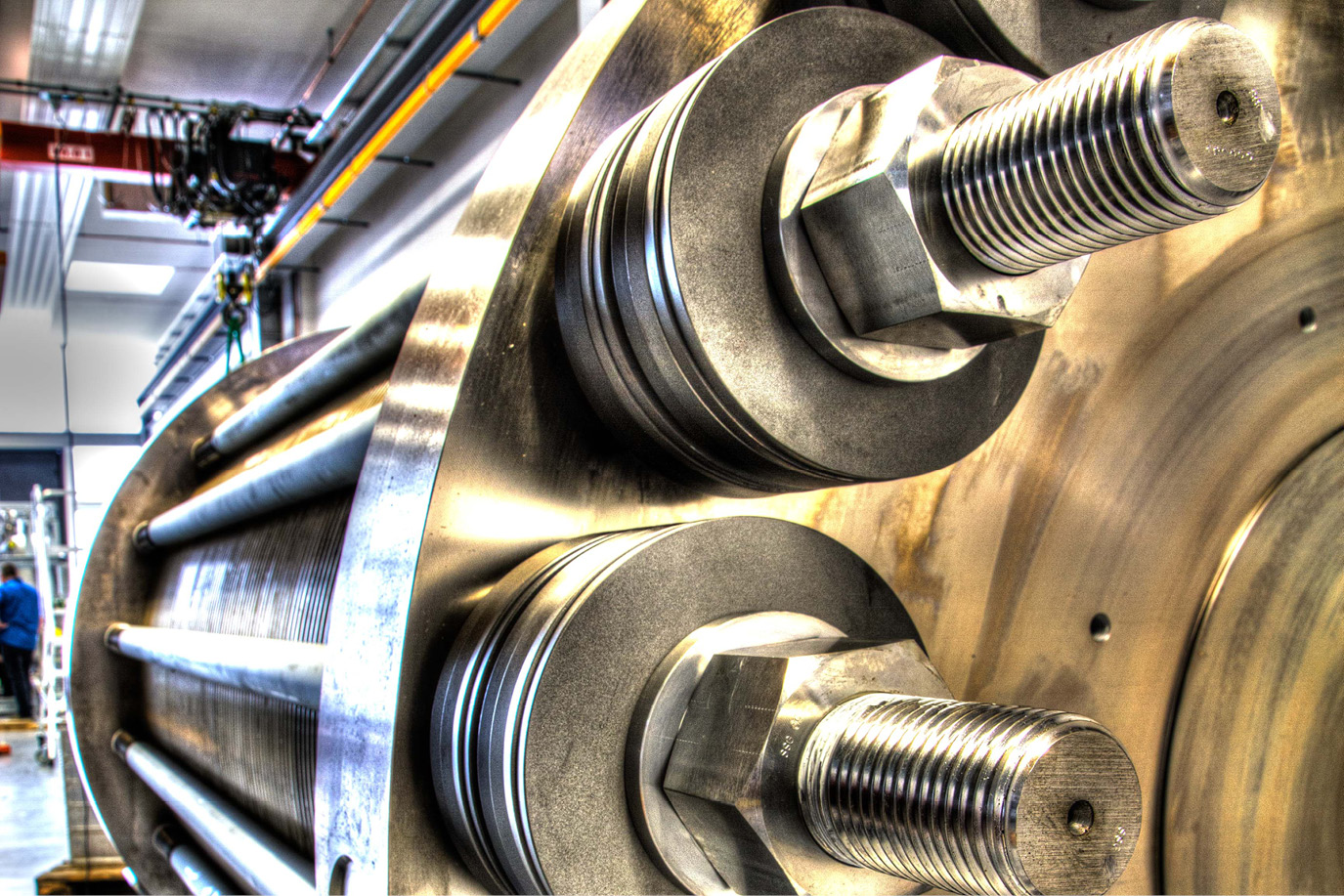

The 6 MW alkaline electrolyzer is a key component of e-gas power plant technology, making it possible to extract hydrogen from water using surplus electricity. Through its expertise, McPhy Energy’s subsidy in Wildau (Germany) has further optimized this technology ( today known as “Alcaline 2.0” electrolysis) and developed in-depth experience ensuring its integration into energy infrastructures such as electrical or natural gas networks.

The plant therefore uses surplus green electricity to produce hydrogen from water in three alkaline electrolyzers. The hydrogen is reacted with CO2 to produce synthetic methane, or Audi e-gas.

It is virtually identical to the fossil fuel and natural gas, and is distributed through an existing infrastructure, the German natural gas network, to CNG filling stations for Audi’s A3 g-tron series. Audi produces up to 1,000 metric tons of e-gas per year, chemically binding some 2,800 metric tons of CO2. This roughly corresponds to the amount that a forest of over 220,000 beech trees absorbs in one year. Water and oxygen are the only by-products.

| Markets

- Industrial hydrogen

- Power to Gas

- Hydrogen territories

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- 6 MW electrolysis solution

Learn more about the solutions in the section: “Equipment & Services”.

| Customer

- Audi

- Location: Werlte (Germany)

- Commissioning: 2013

Read the press release

Gallery

A first reference for maritime mobility in Nantes

• McFilling small capacity allows the refueling of hydrogen-powered public transport vessel

• Port Boyer, Nantes | Commissioning: August 2019

McPhy has commissioned in 2019 a hydrogen station for maritime mobility in Nantes. It allows the refueling of “Jules Verne 2”, a hydrogen-powered public transport vessel.

A French first of its kind in terms of waterways: the “Jules Verne 2” is a hydrogen-powered public transport electric boat for the “Navibus Passeur sur l’Erdre” service. This river service connects Port-Boyer and Petit Port / Faculties and operates all year round.

The ship has an electric power of 2 x 5 kW, its hydrogen consumption is 1.3 kg/day, for a capacity of 12 passengers and 8 bicycle spaces.

A first reference for McPhy in maritime mobility sector.

| Markets

- Hydrogen mobility

- H2 in the territories

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- McFilling small capacity

Learn more about the solutions in the section: “Equipment & Services”.

| Client

- PROVIRIDIS

- Location: Port Boyer, Nantes (France)

- Commissioning: August 2019

For more information, go to the website “Nantes tourisme”

Gallery

A first station in Drôme, the historic birthplace of McPhy

The Community of Valence Romans has entrusted McPhy with installing the first hydrogen refueling station in its community, which is also our company’s historical birthplace.

• Valence, France | Commissioning: 2016

Located in Rovaltain, a few kilometers away from La Motte Fanjas where it was manufactured, our HRS is dedicated to supplying 20 kg of hydrogen per day, at 350 bar, to refuel up to 20 utility vehicles daily (on-site average).

Among them, the Kangoos H2-ZE of the community and the neighboring companies, such as McPhy, of course, and companies like Crouzet, AdVenta and Crédit Agricole as well. And this is only the first stage: about 40 companies have declared that they are interested in hydrogen mobility!

Nicolas DARAGON, President of Valence Romans, talking about the hydrogen station:

“Our approach is pragmatic: we, as a community, have to fight against air pollution to protect our citizens’ health.

This first hydrogen refueling station in Drôme gives a strong message.

I am glad of our pioneering spirit, and I’d like to thank all of the stakeholders who made this project come true: our services of course, but also local companies such as McPhy, who’s a major player in the cutting-edge field of hydrogen.

We hope to inspire other communities and see more and more hydrogen stations throughout local governments.”

| Markets

- Hydrogen mobility

- Hydrogen territories

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- McFilling 20-350

Learn more about the solutions in the section: “Equipment & Services”.

| Customer

- Valence Romans Agglo | Operator: WH2

- Location: Rovaltain (France)

- Commissioning: 2016

Read the press release

Gallery

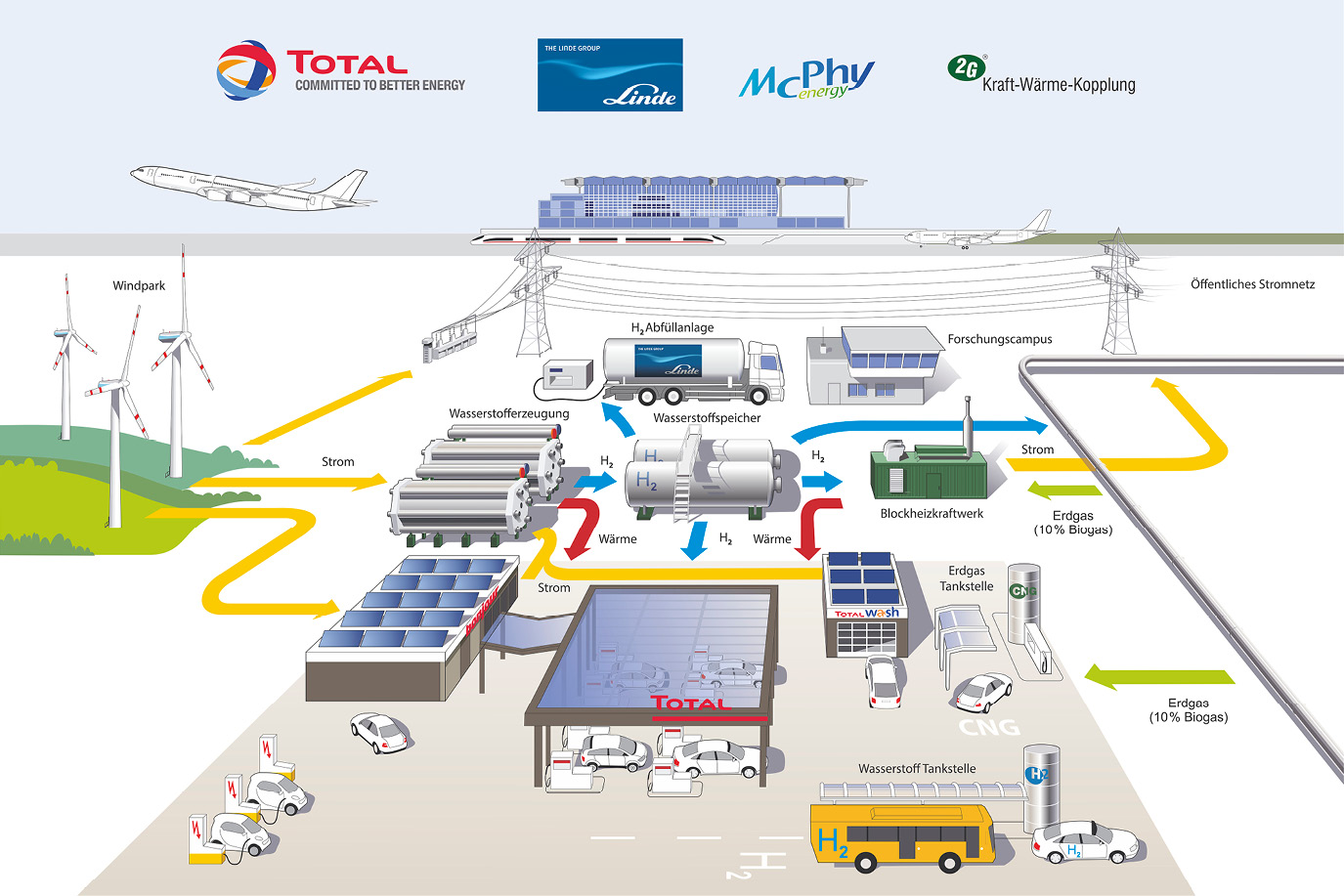

On-site hydrogen production for the first Total hydrogen station in Europe

• A full hydrogen system for mobility and network service

• First high-pressure alkaline electrolyzer on the market

• Connection to a wind farm and grids

• McLyzer performance data collection

• Berlin, Germany | Commissioning: 2014

Located at the Berlin Airport, this demonstration project is designed to produce “green” hydrogen from a surplus of wind power using an electrolyzer and using solid-state storage to create a hydrogen cogeneration plant and hydrogen filling-station infrastructure for buses and cars.

Renewable energy from the Enertrag wind farm near the new airport in Berlin will be converted into hydrogen by a McPhy electrolyzer, to smooth out energy fluctuations and store surplus wind energy.

Total and Linde will build the infrastructure necessary to distribute this fuel to buses and automobiles powered by fuel cells.

In addition, new-generation McPhy solid-state hydrogen-storage will allow the 2G power station to provide electricity or heat from stored hydrogen, flexibly and on demand.

The interests of this project are multiple:

- To produce zero-emission fuel for cars or buses running on hydrogen and/or supply other hydrogen filling stations.

- To re-inject surplus renewable energy into the natural gas network or the power grid.

- To optimize a system that is subject to high constraints with regard to electrical power supply and implement several technological elements.

| Markets

- Hydrogen mobility

- Power to Gas

- Energy storage (wind farm)

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- McLyzer 0.5 MW (250 kg per day)

- McStore 100 kg per day

Learn more about the solutions in the section: “Equipment & Services”.

| Key points

- Location: Berlin (Germany)

- Commissioning: 2014

Gallery

Production and storage of clean hydrogen for industrial processes

• Illustrates the potential of decarbonized hydrogen produced by electrolysis as a feedstock for industry

• Guaranteed industrial performance and energy independence while reducing the environmental footprint of the PUS

• Grenoble, France | Commissioning: June 2018

Since 2018, with three electrolyzers and two storage modules, McPhy offers a complete solution adapted to the significant increase in hydrogen requirements of the Utility Services Unit (PUS) located at the heart of the scientific cluster on the CEA Minatec site in Grenoble.

Guaranteeing industrial performance and energy independence while reducing the environmental footprint of the PUS.

As part of this industrial & mobility project, McPhy designed a production and storage unit offering a suitable response to the significant increase in hydrogen requirements of the Utilities Services Unit.

This production unit demonstrates the potential of zero-carbon hydrogen produced by electrolysis for industry. It is intended to supply hydrogen to CEA’s industrial processes and to the GEG (Gaz Électricité Grenoble) hydrogen station which powers the HyWay project (zero emissions mobility).

The hydrogen production unit is composed of three alkaline electrolyzers which will produce up to 150,000 m3 of hydrogen per year. The hydrogen produced is compressed at 200 bar in a gaseous form; and at 30 bar in a solid form via the McPhy hydrogen storage technology.

This installation is part of the HyWay project led by Tenerrdis.

The HYWAY project aims to promote, promote and validate the technical, economic and environmental relevance of the French model for deploying hydrogen mobility around captive fleets.

| Markets

- Industrial hydrogen

- Hydrogen mobility

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- 3 McLyzer 10-10

- 2 McStore

Learn more about the solutions in the section: “Equipment & Services”.

| Client

- Engie Cofely

- Location: CEA of Grenoble (France)

- Commissioning: June 2018

Read the press release

Gallery

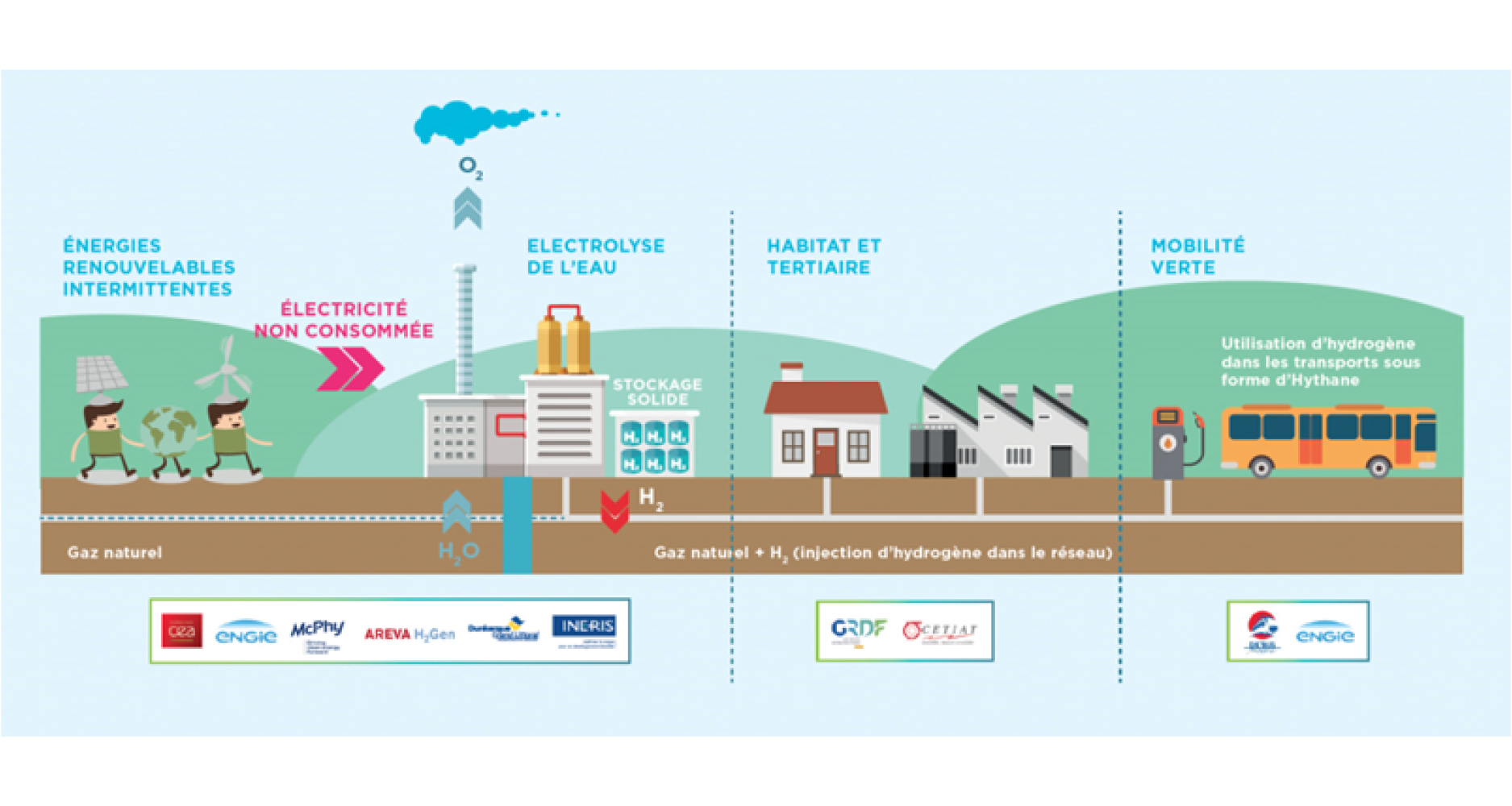

GRHYD: McPhy equips the first Power to Gas demonstrator in France

• The first Power-to-Gas demonstrator in France

• 11 leading partners in zero-carbon energy

• 5 years of study, authorization and demonstration

• 100 homes and the health center boiler supplied by a new gas made up of hydrogen and natural gas

• McPhy provided a McStore solid storage solution to the GRHYD project

The objective of the project is to evaluate and validate the technical and economic relevance of home energy solutions using a natural gas and hydrogen component.

Launched in 2014, GRHYD is a project to inject hydrogen into the territory’s natural gas distribution network in order to meet the needs of the residents of the new neighborhood of Cappelle-la-Grand in terms of heating, hot water and cooking. Approximately 100 homes are supplied with a mixture of hydrogen and natural gas, in variable proportions of hydrogen and less than 20% by volume. The objective of the project is to evaluate and validate the technical and economic relevance of home energy solutions using a natural gas and hydrogen component.

GRHYD is coordinated by ENGIE in association with 10 other partners, it’s supported by the government as part of the Future Investment Program operated by ADEME and labeled by the Tenerrdis competitiveness cluster.

As the first Power to Gas demonstrator in France, GRHYD represents a large-scale demonstration stage, which is the necessary transition between the previous experiments and the ambition of future industrialization of this process.

Inaugurated in 2018, the experimentation ended in 2020.

| Markets

- Power to Gas

- Hydrogen for local communities

- Energy storage

- Research and innovation

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- McStore (McPhy stopped the commercialization of its solid storage solution in December 2018)

Learn more about the solutions in the section: “Equipment & Services”.

| Customer

- ENGIE

- Location: Cappelle-la-Grande, France

- Launch date: 2014, inauguration in 2018, end of experimentation in 2020

Read the press release

A solid-state hydrogen storage solution with a total capacity of 750 kg

Launched in 2014 in Troia, in the region of Apulia, the INGRID platform is an impressive energetic hub putting hydrogen solid state storage at the heart of the project’s architecture.

• 5 storage blocks: 750 kg of stored hydrogen

• Taoia, Italy | Commissioning: 2016

McPhy plays a key role in this project, since the company gives its support based on its considerable expertise in solid-state storage technology to establish its feasibility “at large scale” (750kg of hydrogen stored); and also to demonstrate the economical relevance of the business model generated.

McPhy supplies

- Five storage units

Each one presenting a hydrogen storage capacity of 150 kg, our HDS150 contain the McPhy

Energy disks. The blocks are transportable and, once filled, will be transported to the

final user. - Three hydrogen loading stations

Installed on the INGRID site, they allow the McStore blocks to be filled with the hydrogen produced by the on-site electrolysis unit. - Unloading station

Installed on the final Customer’s site, this unit allows the blocks to release the stored hydrogen and use it for new energetic applications.

Commissioned at the end of 2016, INGRID is a unique platform, a showcase for solid-state hydrogen storage technology.

| Markets

- Energy storage

- Research and Innovation

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- McStore (750 kg)

Learn more about the solutions in the section: “Equipment & Services”.

| Key points

- Location: Troia (Italy)

- Commissioning: end-2016

Watch the video on the Ingrid project.

Gallery

Hydrogen at the service of energy independence in an island environment

The objective of the smart platform installed at the University of Corse Pasquale Paoli in Ajaccio, is to experience both the energy storage and network management technologies in an island environment.

• Hydrogen production and storage in island environments

• Paglia Orba, Corsica, France | Commissioning: 2016

The platform combines various electrical production facilities, among which a photovoltaic array. There, our McLyzer 10-10 produces “green hydrogen” to manage the power fluctuations of intermittently available renewable energy sources and to send power back to the micro-network in the evening.

A second tender process will soon allow the installation to be completed by a hydrogen storage solution, such as LTS / McStore.

If the results are conclusive, hydrogen energy is expected to address new fields of application such as hydrogen mobility and will, hopefully, be disseminated throughout the “Island of Beauty”.

| Markets

- Research and innovation

- Energy storage | Power to Power

- Hydrogen for local communities

Learn more about the H2 applications in the section: “Markets”.

| Equipment & Services

- Electrolyzer McLyzer 10-10

- McStore (planned for the project’s 2nd stage)

Learn more about the solutions in the section: “Equipment & Services”.

| Customer

- Université de Corse Pasquale di Paoli, CNRS, CEA

- Location: Paglia Orba |Corse (France)

- Commissioning : 2016