> New milestone in McPhy’s expansion: Ninth hydrogen station in France, representing a daily potential of 17,000 zero-emission km to help improve air quality

Paris, January 10, 2018 – McPhy (Euronext Paris Compartiment C : MCPHY, FR0011742329) a specialist in hydrogen production, storage and distribution equipment, is today announcing that it has been selected by ENGIE for a new McFilling hydrogen station.

2018 should bring a rich vein of new contracts for the filling stations, which are making large-scale clean hydrogen solutions a realistic proposition

Pascal Mauberger, McPhy’s Chairman and Chief Executive Officer, commented: “This landmark clean mobility deal represents another step forward in our expansion, since this ninth station in France will help to consolidate our position as a leading player in this fast-growing market. What’s more, it is another success for our McFilling stations, which have established a reputation for their reliability and robustness. These hydrogen stations have been successfully rolled out in France and also internationally, including in Singapore and in the United Kingdom. We expect 2018 to bring a rich vein of new contracts for the filling stations, which are making large-scale clean hydrogen solutions a realistic proposition that can help rise to the colossal challenges raised by climate change and the imperative of embracing carbon-free energy.”

McFilling | Fill up on clean energy in less than 5 minutes

This new McFilling station will enable the technicians of ENGIE Cofély to refuel the hydrogen-powered vehicles kitted out by Symbio in less than 5 minutes, doubling their range with zero pollution (no particles, no CO2, no NOx, no noise).

The nine McFilling stations already or now being installed in France represent a daily potential of 17,000 zero-emission km.

Clean mobility represents one of McPhy’s three key areas of expansion

Transport accounts for 30% of energy consumption and is responsible for 40% of CO2 emissions in France. (1)

As a result, using hydrogen helps to reduce the carbon footprint of last-mile logistics and to improve air quality in the urban environment.

Hydrogen definitely has a crucial role to play as an alternative clean fuel in the success of the energy transition and the shift towards a low carbon-intensive society in France. Hydrogen has become a genuine area of excellence. McPhy continues to develop its range of 350- and 700-bar high-capacity filling stations to meet the growing needs of the market and to support its customers with the large-scale roll-out of clean energy solutions.

—

(1) Source: Afhypac report entitled “L’hydrogène accélère en 2017” [Hydrogen gains pace in 2017]

About McPhy

In the framework of the energy transition, and as a leading supplier of hydrogen production, storage and distribution equipment, McPhy contributes to the deployment of clean hydrogen throughout the world.

Thanks to its wide range of products and services dedicated to the hydrogen energy, zero emission mobility and industrial hydrogen markets, McPhy provides turnkey solutions to its clients. These solutions are tailored to our client applications: renewable energy surplus storage and valorization, fuel cell car refueling, raw material for industrial sites.

As a designer, manufacturer and integrator of hydrogen equipment since 2008, McPhy has three development, engineering and production units based in Europe (France, Italy, Germany).

The company’s international subsidiaries ensure a global sales coverage of McPhy’s innovative hydrogen solutions.

McPhy is listed on NYSE Euronext Paris (Segment C, ISIN code: FR0011742329; ticker: MCPHY).

Media relations

NewCap

Nicolas Merigeau

T. +33 (0)1 44 71 94 98

mcphy@newcap.fr

Investor relations

NewCap

Julie Coulot | Emmanuel Huynh

T. +33 (0)1 44 71 20 40

mcphy@newcap.fr

McPhy has participated in the laying of the first stone of “Jupiter 1000”, France’s first Power-to-Gas demonstrator, to help power networks support the energy transition

- A decisive project in the deployment of the Power-to-Gas process in France, one of McPhy’s key markets;

- Ramping up of McPhy: 13.5 MWe of electrolysis in Power-to-Gas, with a potential for 17,000 km of clean mobility / day; first key references on the new carbon-free hydrogen market for industry.

Paris, December 19, 2017 – McPhy (Euronext Paris Compartment C: MCPHY, FR0011742329), specialist in hydrogen production, storage and distribution equipment, has participated in the laying of the first stone of the “Jupiter 1000” demonstrator, France’s first Power-to-Gas demonstrator connected to the natural gas transportation network, in Fos-sur-Mer.

Our pioneering solutions at the forefront of innovation meet the colossal energy storage needs resulting from the energy transition.

Pascal Mauberger, Chairman and Chief Executive Officer of McPhy, says “We are very pleased to be able to provide our expertise in the field of electrolysis to the Jupiter 1000 project, a unique project in France involving all of the Power-to-Gas value chain’s players and enabling the wide-scale deployment of this innovative technology.

Key components of the demonstrator, our PEM and alkaline electrolyzers will enable surplus green electricity to be recycled in the form of hydrogen. For the first time, these two technologies will be compared on an industrial scale and under the same usage conditions, which represents a real breakthrough for our industry.

Lastly, this project clearly illustrates McPhy’s ramping up this year. Indeed, we have deployed numerous projects on our key mobility, Power-to-Gas and industry markets. Our pioneering solutions at the forefront of innovation meet the colossal energy storage needs resulting from the threat of climate change and the necessary transition to carbon-free energy.”

* Proton Exchange Membrane

Power-to-Gas: decompartmentalize electricity and gas networks to make the energy transition a success

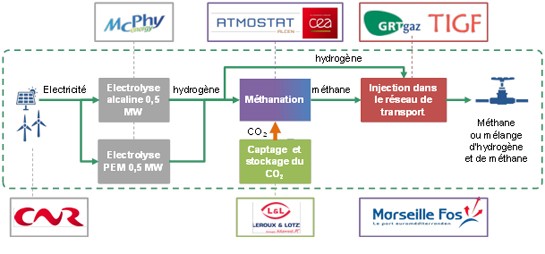

The first Power-to-Gas project connected to the French gas transportation network, baptized “Jupiter 1000”, is being built in Fos-sur-Mer. This 1 MW demonstrator will enable the transition from the concept phase to an industrial tool. The purpose of this unique French project is to test the technical and economic viability of Power-to-Gas, by detecting and dealing with any technical, economic or regulatory difficulties, in order to reduce long-term investment and operating costs, and allow the deployment of a new wide-scale renewable gas production segment.

Coordinated by GRTgaz, this project involves a group of French partners with complementary areas of expertise: McPhy for the electrolysis phase, Atmostat and the CEA (French atomic energy commission) for the methanation reactor, Leroux & Lotz for the CO2 capture technology, the CEA for the R&D, CNR for the supplying of surplus renewables and ensuring the future remote steering of the facility, RTE for the processing of electrical data and GRTgaz and TIGF to manage the injection into gas networks.

Ramping up of McPhy: deployment of innovative solutions at the heart of the global development of clean hydrogen as a key element of the transition to carbon-free energy

_ Clean mobility: acknowledged expertise acclaimed by prestigious partners, deployment of stations offering the potential for 17,000 km per day of clean mobility

- January 2017: McPhy and its partners win the $1 million H2 Refuel H-Prize organized by the U.S. Department of Energy to encourage the development of a competitive small-scale hydrogen station that can become an integral part of the hydrogen refueling infrastructure network and the democratization of fuel cell electric vehicles;

- March 2017: McPhy is granted the exclusive European distribution rights for SimpleFuel™, the compact all-in-one refueling station covering hydrogen generation, compression, storage and distribution for mobility;

- April 2017: inauguration of FaHyence, the first hydrogen station connected to an electrolyzer able to produce hydrogen on-site and on-demand from renewable energies for sustainable mobility;

- July 2017: 1st contract on the UK hydrogen refueling station market for McPhy, which will provide a refueling solution for Riversimple, a Welsh company that is reinventing clean mobility by launching an all-inclusive service for using its hydrogen fuel cell concept cars that reduces environmental and health impacts;

- August 2017: delivery of a McFilling 20-350 station in Singapore for ENGIE’s REIDS project;

- December 2017: inauguration of the Rouen hydrogen station, within the framework of the Eashymob European hydrogen mobility project led by the Normandy Region, the 1st McPhy station installed in a town center.

_ Power-to-Gas: the ability to provide a response to the major issues that are energy storage and network regulation on a market in its deployment phase; 13.5 MW of high-power electrolysis already or currently being installed

- January 2017: On the booming renewable energy storage market, McPhy wins a major contract to supply German green energy firm EnergieDienst with a clean hydrogen production solution on the site of its Wyhlen hydroelectric plant and help it monetize production;

- June 2017: McPhy delivers, to its client Jiantou Yanshan (Guyuan) Wind Energy, a subsidiary of the state-owned manufacturer for Hebei province, 4 MW of hydrogen production equipment, thus strengthening its positioning on multi-MW international projects. This major reference confirms McPhy’s ability to execute large-scale projects for converting renewable energy into hydrogen destined to be injected into the network or used as a commodity;

- September 2017: McPhy wins a €1.3 million international contract to equip the highly-innovative methanation facility operated by Austrian group RAG. The rapid response to variations in the electric power of the solution provided by McPhy allows it to position its equipment as the perfect tool for managing grid stability in the face of growing levels of energy from renewable sources and for participating in primary and secondary reserve;

- December 2017: Laying of the first stone of the “Jupiter 1000” demonstrator, France’s first Power-to-Gas demonstrator connected to the natural gas transportation network, in Fos-sur-Mer. McPhy is contributing its expertise in electrolysis technology to this project.

_Industry: highly-competitive technology enabling industrialists to combine economic performance and environmental efficiency

- July 2017: Following the CPI Zaoquan thermal power plant in China’s Ningxia region, McPhy will equip a power plant in Lebanon for a Power Plant Cooling application. By winning this latest contract for Thyssenkrupp TKUCE, McPhy reaffirms the efficiency of its range of McLyzer generators for the competitively-priced on-site production of the hydrogen required for cooling circuits to operate in thermal power plants;

- December 2017: McPhy delivers, to Linde, the hydrogen production equipment for the Pôle Utilité Services PUS operated by ENGIE Cofély, which supplies Minatec’s semiconductor fabs in Grenoble.

Outlook

2017 saw a real acceleration in the global development of clean hydrogen. McPhy offers technologies at the forefront of innovation that are ready to be deployed and have already been chosen by prestigious partners on a global level.

We are therefore confident in our ability to seize these opportunities that should lead to further buoyant growth in our activity in 2018.

About McPhy

In the framework of the energy transition, and as a leading supplier of hydrogen production, storage and distribution equipment, McPhy contributes to the deployment of clean hydrogen throughout the world.

Thanks to its wide range of products and services dedicated to the hydrogen energy, zero emission mobility and industrial hydrogen markets, McPhy provides turnkey solutions to its clients. These solutions are tailored to our client applications: renewable energy surplus storage and valorization, fuel cell car refueling, raw material for industrial sites.

As a designer, manufacturer and integrator of hydrogen equipment since 2008, McPhy has three development, engineering and production units based in Europe (France, Italy, Germany).

The company’s international subsidiaries ensure a global sales coverage of McPhy’s innovative hydrogen solutions.

McPhy is listed on NYSE Euronext Paris (Segment C, ISIN code: FR0011742329; ticker: MCPHY).

Press relations

NewCap

Nicolas Merigeau

T. +33 (0)1 44 71 94 98

mcphy@newcap.fr

Investor relations

NewCap

Julie Coulot | Emmanuel Huynh

T. +33 (0)1 44 71 20 40

mcphy@newcap.fr

Power-to-Gas continues to gain market traction: McPhy wins a €1.3M equipment contract in Austria for an innovative methanation plant operated by RAG

McPhy’s generator, powered with renewable energy, will provide green hydrogen for a revolutionary underground methanation process.

Thanks to its high dynamic response capabilities, perfectly aligned with the variability of renewable energies, McPhy’s electrolyzer is an ideal tool to provide electricity grid with the flexibility they need.

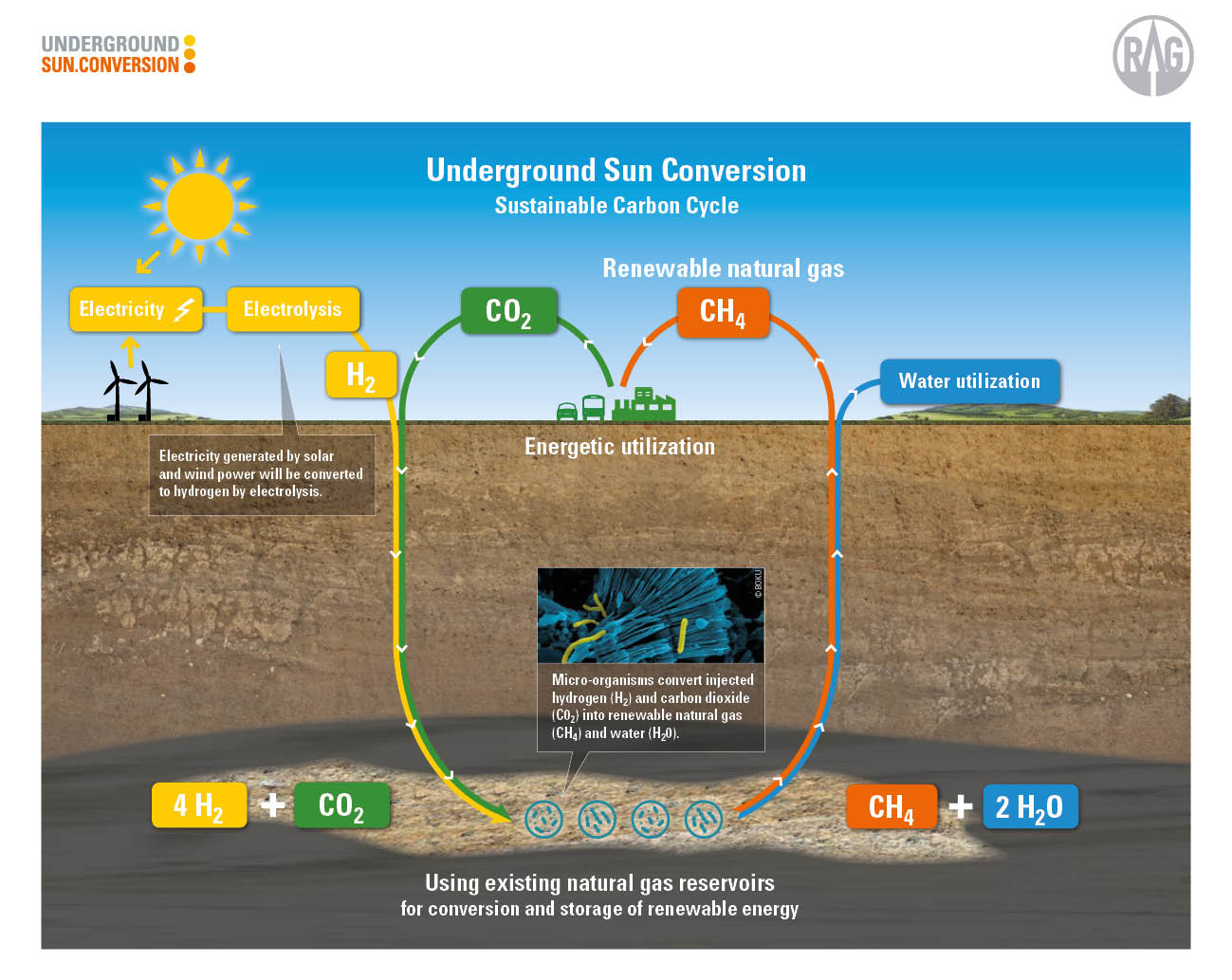

La Motte-Fanjas (Drôme, France), 7 September 2017 – McPhy, the designer, manufacturer and integrator of hydrogen equipment for the energy, transport and industrial sectors, has been selected by RAG, the Austrian underground gas storage specialist, to supply the hydrogen generation system for its highly innovative Underground Sun Conversion project.

RAG has developed an innovative approach to produce and store green methane from hydrogen generated by renewable energies and micro-bacteria. The synthetic natural gas will be produced and stored directly in a natural gas reservoir more than 1,000 m underground, then fed into the pipeline network to be delivered on demand to consumers.

The project is now entering an industrialization phase, enabling RAG to gain reliable knowledge for future business applications.

At the heart of this project, the hydrogen will be generated by a McLyzer 100-30 electrolyzer.

McPhy technology’s decisive benefits for Power-to-Gas applications and grid services

McPhy won this international call for tenders following a thorough selection process with particularly stringent requirements, including: very fast dynamic response to balancing power, delivery of hydrogen directly at 30 bar, technological maturity and system robustness. The McLyzer 100-30 hydrogen generator offered a perfect response to these high expectations.

Power-to-Gas

Key benefits of McPhy’s hydrogen generation equipment

| Dynamic response for fluctuations in electrical power

| High-pressure production

| Outstanding energy efficiency

| Economic competitiveness

| Reliability ant robustness of a mature technology

| Simple use and maintenance

Its dynamic response to follow the fast variations of current coming from renewable energies has been long demonstrated thanks to the data collected since 2014 on the “H2BER” Power-to-Gas project in Berlin.

McPhy’s electrolyzer is positioned as an ideal tool for managing grid stability faced with the growing levels of energy from renewable sources and taking part in primary and secondary reserve.

Designed by McPhy to limit their environmental impacts, its hydrogen generators combine a zero loss purification unit with a closed-loop system to minimize water consumption during its transformation into hydrogen. Their renowned durability will make it possible to support the Underground Sun Conversion industrial project over the long term.

13 MW of Power-to-Gas equipment

“I am delighted that RAG has selected McPhy’s electrolyzer as a core component for its Underground Sun Conversion project. This equipment, which will be commisionned mid-2018, is designed for an automatic operation, with low maintenance requirements. This will enable our client to focus on its core process: the methanation.

With this latest contract, McPhy will soon have installed over 13 MW of Power-to-Gas capacity, representing an overall production capacity close to 6 tons of clean hydrogen per day.

This key reference once again confirms McPhy’s position as a major player for Power-to-Gas thanks to the relevance and modular capabilities of our McLyzer range.”

Pascal Mauberger | Chairman and Chief Executive Officer

About McPhy

In the framework of the energy transition, and as a leading supplier of hydrogen production, storage and distribution equipment, McPhy contributes to the deployment of clean hydrogen throughout the world.

Thanks to its wide range of products and services dedicated to the hydrogen energy, zero emission mobility and industrial hydrogen markets, McPhy provides turnkey solutions to its clients. These solutions are tailored to our client applications: renewable energy surplus storage and valorization, fuel cell car refueling, raw material for industrial sites.

As a designer, manufacturer and integrator of hydrogen equipment since 2008, McPhy has three development, engineering and production units based in Europe (France, Italy, Germany).

The company’s international subsidiaries ensure a global sales coverage of McPhy’s innovative hydrogen solutions.

McPhy is listed on NYSE Euronext Paris (Segment C, ISIN code: FR0011742329; ticker: MCPHY).

Media relations

Calyptus

Marie-Anne Garigue

T. +33 (0)1 53 65 68 63

marie-anne.garigue@calyptus.net

• Revenues multiplied by 2.5 for the first half of the year

• Continued improvement in current operating income

With hydrogen’s deployment as a key driver for the global energy transition, McPhy is moving forward with its strong and sustainable growth.

[La Motte-Fanjas, 27 July 2017]

About McPhy

In the framework of the energy transition, and as a leading supplier of hydrogen production, storage and distribution equipment, McPhy contributes to the deployment of clean hydrogen throughout the world.

Thanks to its wide range of products and services dedicated to the hydrogen energy, zero emission mobility and industrial hydrogen markets, McPhy provides turnkey solutions to its clients. These solutions are tailored to our client applications: renewable energy surplus storage and valorization, fuel cell car refueling, raw material for industrial sites.

As a designer, manufacturer and integrator of hydrogen equipment since 2008, McPhy has three development, engineering and production units based in Europe (France, Italy, Germany).

The company’s international subsidiaries ensure a global sales coverage of McPhy’s innovative hydrogen solutions.

McPhy is listed on NYSE Euronext Paris (Segment C, ISIN code: FR0011742329; ticker: MCPHY).

Media relations

Calyptus

Marie-Anne Garigue

T. +33 (0)1 53 65 68 63

marie-anne.garigue@calyptus.net

First contract on the UK hydrogen refueling station market for McPhy, which will be supplying a hydrogen refueling solution for Riversimple

The Welsh company Riversimple, which is reinventing clean mobility with its launch of an “all-inclusive” service for using its hydrogen fuel cell concept cars Rasa, is McPhy’s first customer on the UK HRS market. McPhy, the French specialist for hydrogen equipment serving the energy, transport and industrial markets, will be supplying Riversimple with a McFilling® refueling solution to conduct a full scale trial of an initial series of 20 Rasa cars.

La Motte Fanjas (Drôme, France) and Llandrindod Wells (Powys, Wales), 25 July 2017 – McPhy, the designer, manufacturer and integrator of hydrogen equipment for the energy, transport and industrial sectors, has been chosen by the hydrogen car manufacturer and mobility services company Riversimple to supply it with a first refueling station.

Perfectly aligned with the Rasa’s technical features, the McFilling® 20-350 will enable its users to fill up with hydrogen in less than five minutes to travel 500 km without any health or environmental impacts. Riversimple and McPhy, two pioneers for green hydrogen technologies, are working towards affordable zero emission mobility.

With this first contract, McPhy is entering the UK clean mobility market, which is developing strongly thanks in particular to an ambitious government support program. After announcing in March this year that a further €26m budget would be made available, the UK government will soon be launching a call for projects to deploy stations and promote the adoption of hydrogen-powered electric vehicles.

Unique touring car and business model making it possible to eliminate environmental and public health impacts

The Rasa is a two-seater coupé with a range of 500 km on a full tank of just 1.6 kg of hydrogen at 350 bar of pressure. Its use of a low-powered fuel cell enables it to reach a speed of 100 kph, while it weighs in at just 580 kg thanks to its composites-based chassis and gearbox-free design. This lightweight design is coupled with an inventive powertrain, which means that the Rasa is one of the world’s most efficient vehicles. It is fitted with four motors (one per wheel), which also act as brakes and recover more than 50% of the energy generated by braking to store it in capacitors, send it back to the motors again and provides the energy to accelerate, and was developed with support from the Welsh government.

This next-generation vehicle will be offered as an “all-inclusive” service, including use of the car, maintenance, tyre replacement, assistance, insurance and fuel.

Full-scale trial with an initial series of 20 Rasa cars will be starting up at the end of 2017 for one year. This test will be carried out in Abergavenny, Monmouthshire, Wales, and will involve around 100 beta testers. The McFilling® hydrogen refueling solution will be a core part of this system. The trial is partially funded by a grant from the European Union.

With McFilling®, McPhy is energizing zero emission mobility

The 20-350 model from the McFilling® range delivers 20 kg of hydrogen per day at a pressure of 350 bar. With its modular, scalable and turnkey design, like all the HRS developed by McPhy, the McFilling® 20-350 has been created for refueling captive fleets with unit capacities up to 6 kg.

Out of the 20 hydrogen refueling stations currently in service in France, eight already use McFilling® solution. They include the Sarreguemines station, the first station combined with an electrolyzer to produce clean hydrogen on-site and on-demand for refueling vehicles.

Committed to driving clean energy forward

“We are delighted that Riversimple has chosen our McFilling® solution to support the project to develop the Rasa, its innovative vehicle, which is opening up the future of affordably-priced clean mobility. We have welcomed the Riversimple team at the demonstration platform for our hydrogen stations in France and they share our vision: “Committed to driving clean energy forward”. This contract will enable us to enter the UK hydrogen mobility market, which is starting to take off”, concludes Pascal Mauberger, McPhy Energy’s Chairman and Chief Executive Officer.

“We are impressed with the simplicity and elegance of McPhy’s refueling solutions and are looking forward to installing the first one on UK soil”, confirms Dr Stafford Lloyd, Riversimple’s Systems and Sustainability Engineer, who is leading the refueling station project for the company.

Download the release [PDF]

About McPhy

In the framework of the energy transition, and as a leading supplier of hydrogen production, storage and distribution equipment, McPhy contributes to the deployment of clean hydrogen throughout the world.

Thanks to its wide range of products and services dedicated to the hydrogen energy, zero emission mobility and industrial hydrogen markets, McPhy provides turnkey solutions to its clients. These solutions are tailored to our client applications: renewable energy surplus storage and valorization, fuel cell car refueling, raw material for industrial sites.

As a designer, manufacturer and integrator of hydrogen equipment since 2008, McPhy has three development, engineering and production units based in Europe (France, Italy, Germany).

The company’s international subsidiaries ensure a global sales coverage of McPhy’s innovative hydrogen solutions.

McPhy is listed on NYSE Euronext Paris (Segment C, ISIN code: FR0011742329; ticker: MCPHY).

Media relations

Calyptus

Marie-Anne Garigue

T. +33 (0)1 53 65 68 63

About Riversimple

Riversimple is designing and manufacturing highly efficient hydrogen cars in Wales.

Riversimple is a consortium member of SWARM (Demonstration of Small 4-wheel fuel cell passenger vehicle Applications in Regional and Municipal transport). SWARM has received FCH-JU (Fuel Cells and Hydrogen Joint Undertaking) research funding from the European Union.

Media contact

Catherine Kelly

T. +44 (0)7704 130226

ckellypr@gmail.com

Following the CPI Zaoquan thermal power station in China’s Ningxia region, McPhy will be equipping a power station in Lebanon for a Power Plant Cooling application. With this latest contract, McPhy is confirming the efficiency of its range of McLyzer generators for competitively-priced on-site production of the hydrogen required for cooling circuits to operate in thermal power plants.

La Motte Fanjas, 19 July 2017 – McPhy, the designer, manufacturer and integrator of hydrogen equipment for the energy, transport and industrial sectors, is supporting its partner ThyssenKrupp Uhde Chlorine Engineers (TKUCE), specialized in comprehensive high-yield electrolysis solutions and technologies, to renovate a thermal power plant in Lebanon.

With this project, McPhy will be supplying two McLyzer 10-10 generators to equip the cooling systems for the plant’s alternators, while TKUCE will be in charge of engineering.

Strong market growth for on-site hydrogen production equipment

The market for on-site hydrogen production equipment for Power Plant Cooling applications is growing strongly, particularly in emerging regions where hydrogen logistics infrastructures are relatively underdeveloped, which can make their supply costs very high. By replacing deliveries of hydrogen cylinder, McPhy’s solutions are making it possible to ensure reliable supplies, while creating value for their users, which can produce hydrogen for lower costs.

With a unit capacity of 10 Nm3/h of hydrogen delivered at a pressure of 10 bar, the McLyzers that will be deployed at the Lebanese thermal power station will produce hydrogen for injection into its alternator cooling circuit.

For this contract, the Group will be capitalizing on its expert logistics capabilities for export projects.

McPhy, which delivered a first McLyzer 10-30 to the Chinese thermal power station CPI Zaoquan (Ningxia region) at the start of 2017, is confirming its deployment on the high-potential market for on-site hydrogen production.

On-site hydrogen production equipment | McLyzer

About McPhy

In the framework of the energy transition, and as a leading supplier of hydrogen production, storage and distribution equipment, McPhy contributes to the deployment of clean hydrogen throughout the world.

Thanks to its wide range of products and services dedicated to the hydrogen energy, zero emission mobility and industrial hydrogen markets, McPhy provides turnkey solutions to its clients. These solutions are tailored to our client applications: renewable energy surplus storage and valorization, fuel cell car refueling, raw material for industrial sites.

As a designer, manufacturer and integrator of hydrogen equipment since 2008, McPhy has three development, engineering and production units based in Europe (France, Italy, Germany).

The company’s international subsidiaries ensure a global sales coverage of McPhy’s innovative hydrogen solutions.

McPhy is listed on NYSE Euronext Paris (Segment C, ISIN code: FR0011742329; ticker: MCPHY).

Media relations

Calyptus

Marie-Anne Garigue

T. + 33 (0)1 53 65 68 63

marie-anne.garigue@calyptus.net

As expected, McPhy delivered the Power-to-Gas platform to its customer Jiantou Yanshan (Guyuan) Wind Energy, confirming its expertise in executing major clean hydrogen production projects.

La Motte Fanjas, 29 June 2017 – McPhy, the designer, manufacturer and integrator of hydrogen equipment for the energy, transport and industrial sectors, announces the delivery to Jiantou Yanshan (Guyuan) Wind Energy, a subsidiary of the state-owned manufacturer Hebei Construction and Investment Group Co., Ltd, operating in the Hebei province of China, of 4 MW hydrogen production equipment for a Power-to-Gas application. Combined with a solid-state hydrogen storage solution, the McPhy system makes it possible to transform green energy and store the surplus energy generated by a 200 MW wind farm.

11 MW Rapid Response Electrolysis delivered worldwide

This delivery raises the total power of large capacity hydrogen generators delivered by McPhy to 11 MW.

Perfectly adapted to intermittent renewables, this rapid response hydrogen generation equipment provides energy companies with a valid solution for maintaining the stability of electrical networks. Recognized for their high efficiency, robustness, ease-of-integration, McPhy equipment is specifically designed to limit installation and operating costs.

The system delivered to the Hebeï province is a 4 MW compact model including two McLyzer 400 modules, transformers, power electronics, a purification and drying unit and a solid-state storage module. It is scheduled to be installed and commissioned at the end of the year, initiating in the heart of China a complete value chain for surplus electricity of renewable origin.

McLyzer stacks | McPhy Italia plant in San Miniato (Italy)

Expertise in the management of international projects

Operations scaled for successfully executing international projects

This major reference confirms McPhy’s ability to execute large-scale projects for converting renewable energy into hydrogen destined to be injected into the network or used as a commodity.

McPhy has implemented optimized processes for sourcing, packaging and delivery, thus demonstrating its expertise in the logistics for projects for the expert segment of major international regions.

After the customer requirements specification phase, McPhy equipment is preassembled in containers to facilitate their transport, unloading and assembly on-site with the objective of global performance.

“Whereas energy transition is leading to large-scale installations for the production of renewable electricity, energy companies are faced with the challenge of managing the intermittency of the supply to electrical networks. Based on nearly 10 years of experience in hydrogen production and storage solutions, we propose, wherever they are located, custom-designed solutions to ensure a balance between energy supply and demand in their networks. Our design, production, delivery and installation chain is now properly scaled to support this international development strategy”, concluded McPhy’s Chairman and CEO, Pascal Mauberger.

About McPhy

In the framework of the energy transition, and as a leading supplier of hydrogen production, storage and distribution equipment, McPhy contributes to the deployment of clean hydrogen throughout the world.

Thanks to its wide range of products and services dedicated to the hydrogen energy, zero emission mobility and industrial hydrogen markets, McPhy provides turnkey solutions to its clients. These solutions are tailored to our client applications: renewable energy surplus storage and valorization, fuel cell car refueling, raw material for industrial sites.

As a designer, manufacturer and integrator of hydrogen equipment since 2008, McPhy has three development, engineering and production units based in Europe (France, Italy, Germany).

The company’s international subsidiaries ensure a global sales coverage of McPhy’s innovative hydrogen solutions.

McPhy is listed on NYSE Euronext Paris (Segment C, ISIN code: FR0011742329; ticker: MCPHY).

Press contact

Calyptus

Marie-Anne Garigue

T. + 33 (0)1 53 65 68 63

marie-anne.garigue@calyptus.net

For the first time in Europe, McPhy will be presenting SimpleFuelTM, the all-in-one hydrogen station, at the Hannover Messe trade fair

Join us in Hall 27, Stand D70 from 24 to 28 April

For the first time ever in Europe, McPhy will be presenting an exclusive preview of the SimpleFuelTM hydrogen refueling station at the 2017 Hannover Messe trade fair, the world’s leading industrial technology event. McPhy is the exclusive distributor in Europe for this solution, which it has jointly developed in the US to facilitate the widespread adoption of zero emission mobility. With its compact, all-in-one design, SimpleFuelTM is a fully integrated hydrogen generation, compression, storage and dispensing system, serving commercial fleets, car dealerships, service stations, logistics platforms…

[La Motte Fanjas, 24 april 2017]

McPhy, the designer, manufacturer and integrator of hydrogen equipment for the energy, transport and industrial sectors, will be presenting the SimpleFuelTM hydrogen refueling station at the 2017 Hannover Messe trade fair from 24 to 28 April. The Group, which has jointly developed SimpleFuelTM with its US partners Ivys Energy Solutions and PDC Machines, manages its production at its San Miniato plant (Italy) and has exclusive distribution rights for Europe. Preorders are being taken, with the first deliveries scheduled for the end of 2017.

SimpleFuelTM is a turnkey, compact and affordable refueling station. A genuine “energy hub”, it is a fully integrated hydrogen generation, compression, storage and dispensing system capable of delivering 5-10 kg/day at pressures up to 700 bar. In January this year, the US Department of Energy (DOE) awarded the $1 million first prize from its H2 Refuel H-Prize competition to SimpleFuelTM. This competition, organized by the Hydrogen Education Foundation (HEF), aimed to promote the development of on-site affordable small-scale hydrogen refueling systems with a view to accelerating the deployment of hydrogen infrastructure across the US to contribute to the widespread adoption of zero emission mobility.

The compact physical footprint of SimpleFuel™ offers extensive opportunities for installation at all types of locations, even space-constrained, both indoors and outdoors: commercial fleets, car dealerships, service stations, logistics platforms…

“We have worked closely with our US partners over the last two years on the technological and industrial development of this revolutionary hydrogen refueling station combining performance, affordability and accessibility. With SimpleFuel™, hydrogen is simpler than ever. Easy to install, all-in-one and user-friendly, SimpleFuel™ will accelerate the deployment of hydrogen infrastructures. In this way, it will facilitate the widespread adoption of zero emission mobility, while making it possible to monetize renewable energy surplus”, concluded McPhy’s Chairman and CEO, Pascal Mauberger.

On 26 April, from 2:40 pm, Bertrand Amelot, McPhy’s Executive Vice President Sales & Marketing, will be speaking about “SimpleFuel™: game-changing H2 refueling station – an all-in-one production, storage and dispensing solution” during the “Hydrogen + fuel cells + batteries” public forum in Hall 27, Stand C66.

Commissioning of the first H2 refueling station in France producing green hydrogen on!

[11 April 2017]

On 11 April 2017, the hydrogen refueling station of the FaHyence project was officially commissioned in the presence of Mr. Roland Roth, President of the Communauté d’agglomération Sarreguemines Confluences (CASC) and Didier Vaucois, the EDF Grand Est Regional Director, as well as partners of the project and hydrogen vehicle users. This represents the first hydrogen refueling station in France able to produce hydrogen on-site and on-demand from renewable energies for sustainable mobility!

This achievement is the product of two years of close collaboration between CASC, EDF, McPhy and EIFER who have associated their expertise to design, scale and build an installation unique in France: the station is equipped with an electrolyzer that produces hydrogen on-site from green electricity and water. Symbio delivered six Kangoo H2-type vehicles to different public and private users who now use hydrogen for their daily professional activities.

Background

As part of its energy transition strategy, the CASC developed a climate plan that includes four strategic priorities focusing on low carbon mobility, and including hydrogen. The “FaHyence project” consists in creating a multi-energy service station that allows users to refuel their electric vehicles with electricity or hydrogen produced on-site. A CNG refueling station is also under study. The CASC is the owner and operator of the station.

The project

EDF, through its Grand Est Regional Delegation and its R&D, as well as the EIFER Institute, co-developed the demonstrator and provided their technical expertise to the CASC, from scaling the equipment to the station’s installations, as well as in obtaining financing and developing a a monitoring and intelligent control system. Electrical energy and in this way the consumed consumed during renewable energy production peaks, outside the peak consumption periods. EDF also supplies the station with green energy guaranteed by certificate of origin.

McPhy designed, manufactured and integrated the first hydrogen system in France, combining an innovative high energy-efficient electrolyzer with a hydrogen station with a capacity of 40 kg per day. Adapted to different vehicle models and with a capacity for 25 recharges per day at 350 bar, this station contributes to cross-border hydrogen mobility with Germany and Benelux with refueling completed in just a few minutes. Autonomous, the station’s electrolyzer system is configured to trigger the control for the production of hydrogen automatically and ensures the continuous availability of the equipment.

McPhy supports the CASC in operating the equipment throughout the project and also supplied a temporary hydrogen refueling during the design and construction phase.

Symbio has developed a Renault Kangoo ZE-type (electric/hydrogen) equipped with a 22 kWh battery and a 5 kW fuel-cell serving as a range extender which recharges the battery in real-time. This solution makes it possible to double the vehicle’s autonomy from 150 km to 300 km. The battery can also be recharged on the electrical network when the vehicle is parked or by a fuel cell installed in the vehicle. A Kangoo ZE-H2 can carry 1.8 kg of hydrogen and be refueled in just a few minutes in an hydrogen station.

FaHyence falls within the scope of H2ME European project, financed by the FCH JU European program that seeks to deploy 29 hydrogen refuelling stations and more than 300 vehicles by 2020.

The FaHyence project in this way is accelerating the energy transition for travel by offering a concrete solution for sustainable mobility, while at the same time addressing the needs of private and professional users in terms of autonomy and refueling time. Finally, it strengthens Europe’s footprint by locating the first French hydrogen refueling station able to produce hydrogen on-site and on-demand in one of its main mobility corridors at the crossroads of France, Germany and Benelux.

| About the Communauté d’Agglomération Sarreguemines Confluences

The Communauté d’Agglomération Sarreguemines Confluences or CASC is a French regional inter-community authority located at the frontier of the French Grand Est region and Germany. It includes 38 districts and 66,000 inhabitants, including the town of Sarreguemines.

After obtaining the French green energy label (“Territoire à Energie Positive pour la Croissance Verte” or TEPCV), the CASC has chosen to gradually incorporate a cross-cutting climate and energy approach in its policies. Accordingly, for nearly 8 years, an important program of actions has been deployed locally to develop a number of projects for the territory’s energy transition and economic development and to raise awareness of the population to sustainable development issues. With the support of its local partners, the CASC has decided to focus its efforts in the area of sustainable mobility on alternative and innovative solutions such as hydrogen to reduce greenhouse gas emissions and position the territory in strong growth potential sectors.

http://www.agglo-sarreguemines.fr

| About EDF

A key player in energy transition, the EDF Group is an integrated electricity company, active in all areas of the business: generation, transmission, distribution, energy supply and trading, energy services. A global leader in low-carbon energies, the Group has developed a diversified generation mix based on nuclear power, hydropower, new renewable energies and thermal energy. The Group is involved in supplying energy and services to approximately 37.1 million customers, of which 26.2 million in France. The Group generated consolidated sales of €71 billion in 2016.

By investing more than €1 billion a year in this territory, EDF is the largest industrial investor in the Grand Est region. EDF partners with local authorities on issues relating to energy transition: that is the reason for our engagement to promote new means of transportation associated with electrical mobility exemplified by this local experimentation. By putting innovation and research at the heart of its strategy, the EDF group demonstrates its know-how and engagement in these territories. EDF is listed on the Paris Stock Exchange.

https://www.edf.fr

| About EIFER

Created in September 2001, EIFER, the European Institute for Energy Research, is an economic interest grouping between EDF (Electricité de France) and KIT (Karlsruhe Institute of Technology). Located in Karlsruhe, Germany, EIFER has a multidisciplinary team of 100 people of different nationalities. In partnership with other international research centres, EIFER’s goal is to create value for its two members and their respective partners: cities, local communities and industries. EIFER focuses on three strategic priorities: sustainable cities, analysing trends and interactions within energy systems, developing local energy concepts and solutions. A team of approximately 15 researchers is devoted to work on hydrogen and fuel cells.

https://www.eifer.kit.edu/

| About McPhy

As a specialised supplier of hydrogen production, storage and distribution equipment, McPhy contributes to the deployment of clean hydrogen as a solution for achieving energy transition. Through its wide range of products and services dedicated to the hydrogen energy, zero emission mobility and industrial hydrogen markets, McPhy provides turnkey solutions tailored to client applications: renewable energy surplus storage and monetization, fuel cell car refueling, raw material for industrial sites As a designer, manufacturer and integrator of hydrogen equipment since 2008, McPhy has three development, engineering and production units based in Europe (France, Italy, Germany). The company’s international subsidiaries ensure a global sales coverage of McPhy’s innovative hydrogen solutions.

http://www.mcphy.com

| About Symbio

Symbio is the French hydrogen leader offering innovative sustainable mobility solutions that extend electric vehicle ranges for greater autonomy make it possible to reduce air pollution in cities and contribute to a low-carbon economy. Symbio designs, manufactures and sells fuel cell vehicles (Kangoo ZE-H2) and hydrogen fuel cell kit systems (5 kW to 300 kW) for integration in all types of vehicles for an operating use identical with internal combustion engines. Symbio has positioned renewable hydrogen energy at the heart of its development strategy. Symbio is in this way pursuing development of clean hydrogen energy applications by participating in different cutting-edge development programs with key industrial and research partners like CEA, ENGIE and Michelin.

http://www.symbiofcell.com

“These activities have received funding from the European Union under the HORIZON 2020 program through the Fuels Cells and Hydrogen Joint Undertaking under subsidy agreement number°671438.

The authors of this document have sole responsibility for its content, and the European Union is not responsible for any use that may be made of the information contained therein.”